IREM

SECTIONS:

The company

IREM – Company producing electronic and electromechanical equipment

Since 1947, IREM has been manufacturing a wide range of equipment that improves the quality of the electrical power supply used by professional users susceptible to voltage anomalies in distribution networks. In order to function properly, all electrical equipment requires a power supply with characteristics compliant with the manufacturer’s specifications. When this condition is not met, failures, errors, and premature aging occur. To prevent this, devices with varying levels of effectiveness are available. The choice must be made by evaluating the level of protection to be guaranteed, the extent of the anomalies to be corrected, and the direct and indirect costs they may cause.

Single-phase and three-phase electrodynamic voltage stabilizers;

Single-phase and three-phase electronic and electrodynamic power conditioners;

Single-phase and three-phase uninterruptible power supplies;

- Products

SINGLE-PHASE AND THREE-PHASE VOLTAGE STABILIZERS

Ministab and Sterostab, industrial voltage stabilizers

We provide voltage stabilizers in Italy for industrial users that need to use electrical grids prone to voltage disturbances. These solutions are widely used for industrial plants in developing countries where the electrical grid is of lower quality.

Line faults, atmospheric phenomena, constant load variations, and disturbances generated by the users themselves make it impossible to guarantee each user a constant voltage within the tolerance margin established by supply contracts.

Often, this tolerance is insufficient for the most susceptible users. Other times, the grid voltage reaches levels that exceed the nominal value by 15, 20, or even 30%.

Voltage fluctuations are particularly insidious disturbances because they are not obvious, but can only be detected with the use of specific equipment. In their presence, electrical users appear to be operating correctly, but this actually masks serious, sometimes irreparable, problems.

Ministab and Sterostab are the registered names of two series of electrodynamic voltage stabilizers that represent a reliable, proven, and cost-effective solution to disruptions caused by voltage fluctuations. Using Ministab and Sterostab is a true investment because eliminating disruptions means reducing costs and increasing productivity.

Both are available in single-phase and three-phase solutions, covering various power ranges.

Ministab: 1 – 120 kVA;

Sterostab: 15 – 800 kVA.

Voltage stabilizers MINISTAB

Voltage stabilizers Ministab

They deliver stabilized true RMS voltage even in the presence of strong harmonic distortions in the electrical distribution network.

The MINISTAB range models are available in single-phase and three-phase versions, ranging from 1 to 120 kVA:

- M models: single-phase stabilizers;

- T models: three-phase stabilizers with phase-average regulation;

- Y models: three-phase stabilizers with independent phase regulation.

Standard nominal voltages:

- Single-phase 230 V;

- Three-phase 400 V

Special nominal voltages:

- single phase 100, 110, 115, 120, 127, 200, 220, 230, 240, 265 and 277 V;

- three-phase 208, 220, 230, 240, 380, 400, 415, 440, 460, 480 and 500 V.

Compensation capacity: symmetrical from ± 10% to ± 30% and asymmetrical up to + 15% – 35%.

Frequency: 50 or 60 Hz.

Accuracy: ±0.5% to ±1.5%.

Open version: IP00.

Indoor versions: IP20, IP21, IP31, and IP54.

Outdoor versions: IP44 and IP54.

Voltage stabilizers STEROSTAB

Stabilizzatori di tensione STEROSTAB

They deliver a stabilized voltage at the true RMS value even in the presence of strong harmonic distortions in the electrical distribution network. The models in the STEROSTAB range are available, for power ratings from 15 to 800 kVA, in single-phase and three-phase versions:

- M models: single-phase stabilizers;

- T models: three-phase stabilizers with phase-average regulation

- Y models: three-phase stabilizers with independent phase regulation

Standard nominal voltages:

- single phase 230V;

- three-phase 400V.

Special nominal voltages:

- single phase 100, 110, 115, 120, 127, 200, 220, 230, 240, 265 and 277 V

- three-phase 208, 220, 230, 240, 380, 400, 415, 440, 460, 480 and 500 V

Compensation capacity: symmetrical from ± 10% to ± 30% and asymmetrical up to + 15% and – 35%. Frequency: 50 or 60 Hz. Accuracy: from ± 0.5% to ± 1.5%. Open version: IP00. Indoor versions: IP20, IP21, IP31 and IP54. Outdoor versions: IP44 and IP54

Specifications:

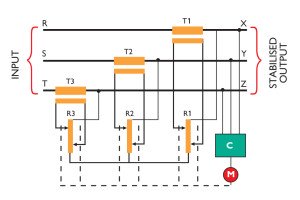

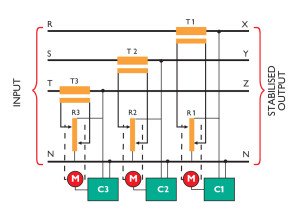

Technology and operation

Ministab and Sterostab regulate using a series transformer. An electronic control circuit detects the output voltage and compares it with a reference voltage. If the difference between the output voltage and the reference voltage exceeds the established tolerance limits, an error signal is generated, negative or positive depending on whether the output voltage is lower or higher than the set value. This signal controls the servomotor that moves the moving contacts (electrographitic rollers/brushes) of the variable autotransformer, changing its transformation ratio in order to provide the primary winding of the series transformer with the additive or subtractive voltage necessary to bring its value back within the preset limits. The output voltage is stabilized on the effective value (RMS) and is therefore not affected by possible harmonic distortions present on the power line. This regulation system has the advantage of not having moving contacts in series with the power line.

Versions

The three-phase ranges are available in two versions:

- The T models stabilize on the average of the three phases and are therefore suitable for balanced networks and for a maximum load imbalance between phases of 50%. The T3 models, being equipped with a single stabilization circuit that simultaneously regulates the three phases, are significantly lower cost. They can also be connected to lines without a neutral.

- The Y models are equipped with an independent stabilization circuit for each phase and are therefore suitable for unbalanced networks and loads with phase imbalances of up to 100%. For the Y3 stabilizers to operate, the neutral connection is essential. The input line must therefore have 4 wires (3 phases + neutral).

Stabilizers do not transform the voltage and provide the same nominal output value as the input voltage. If different nominal voltages are required between input and output, an isolation transformer or autotransformer must be added. Ministab and Sterostab operate correctly on both 50 and 60 Hz networks.

Degrees of protection

Ministab and Sterostab can have different degrees of protection:

IP21: degree of protection suitable for devices installed indoors and in rooms free from dust and splashes;

IP54 INDOOR: guarantees the protection of the stabilizer against dust and splashes, therefore suitable for devices installed in dusty and very hot rooms, but not suitable for outdoor installation;

IP54 OUTDOOR:suitable for outdoor installation as it guarantees the protection of the stabilizer against dust, splashes and solar radiation.

Distribution/Sales throughout Italy

We distribute voltage stabilizers and provide assistance mainly throughout Italy.

LINE CONDITIONERS: MINISTATIC AND STEROGUARD

These devices are designed to provide the highest level of protection for electrical users connected to lines experiencing voltage fluctuations, high-frequency disturbances, and voltage spikes. These phenomena statistically account for over 95% of electrical anomalies, which are sources of faults and disruptions for any type of user connected to distribution networks. The standard models combine four different devices in a single device, each dedicated to compensating for or mitigating a specific electrical anomaly:

- a surge suppressor,

- a mains filter,

- a high-attenuation isolation transformer,

- a voltage regulator.

The range consists of models with power ratings ranging from 0.5 to 930 kVA, which utilize two different voltage regulation technologies:

a) static switching technology for loads with absorption up to 4 kVA single-phase and 24 kVA three-phase: MINISTATIC;

b) electrodynamic regulation technology using a series transformer and variable autotransformer for loads with absorption up to 950 kVA three-phase: STEROGUARD. The two regulation technologies and the breadth of the range allow us to provide the most suitable regulation system to meet the specific needs of the various types of loads being powered.

Ion Science produces a wide range of high-tech products. VOC meters, leak detectors, benzene monitors, mercury analyzers, and corrosion monitors are distributed and renowned worldwide. Their gas detectors are used in a wide range of environmental, petrochemical, chemical, indoor air quality, landfill, and biogas plant applications, to name a few.

MINISTATIC electronic air conditioners

MINISTATIC electronic air conditioners

They have specific performance characteristics for powering low-to-medium power electronic equipment that requires particularly high stabilization speed, such as process control, numerical control, robots, electromedical equipment, telecommunications equipment, and computers.

The range includes standard models with power ratings from 0.5 to 24 kVA. Furthermore, since the construction criteria make these air conditioners highly versatile, versions with customized features can be designed upon request for a wide variety of applications.

TS Single-Phase Series

The range includes single-phase models with power ratings from 500 VA to 4 kVA. Their absolute silence, compact size, and ease of use and installation make them suitable for use in offices, studios, and laboratories, as well as in professional applications in the automotive, chemical, food, and telecommunications industries.

Request technical documents for this model

TS Three-Phase Series

This range includes three-phase models with power ratings from 12 to 24 kVA. It is particularly suitable for powering CNC machine tools, automation systems, and telecommunications systems.

Equipped with a delta-star isolation transformer, they generate a “clean neutral” and consequently also provide a 230 V single-phase voltage using a 400 V three-phase system without a neutral.

STEROGUARD electrodynamic air conditioners

STEROGUARD electrodynamic air conditioners

They provide the highest level of protection for high-power loads with high electromagnetic susceptibility, connected to grids subject to voltage fluctuations, high-frequency conducted disturbances, and voltage spikes.

The regulation system consists exclusively of magnetic components capable of withstanding loads with high inrush currents. The use of electronic components is limited to grid control and the control of the magnetic components that stabilize the voltage. Thanks to these characteristics, electromechanical line conditioners are distinguished by their high electromagnetic immunity and absolute reliability. They are therefore particularly suitable for powering radio and television transmitters, telephone systems, radar systems, motors, compressors, pumps, electromedical equipment, machine tools, etc.

Their simple construction means that any technical interventions can be carried out even by technicians with basic knowledge of electrical installations.

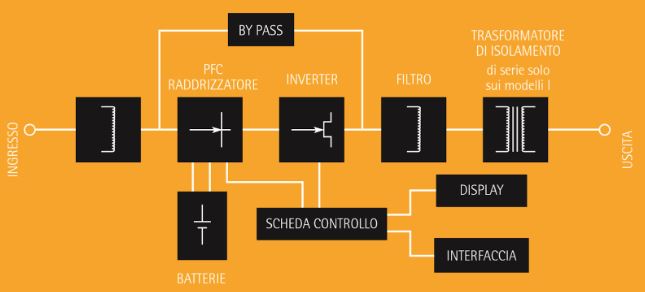

UPS: MINIPOWER AND STEROPOWER

Minipower and Steropower, double-conversion ON-Line UPS systems, are professional devices designed to ensure the highest level of protection for: high-value appliances that manage processes and operations whose interruption would cause significant damage and/or risks; and sensitive electronic appliances installed in industrial environments where, in addition to power outages, highly disruptive electrical transients and strong harmonic distortions occur. They are therefore particularly suitable for protecting, with maximum reliability, sensitive and mission-critical appliances such as medical devices, computer systems, telecommunications systems, computer networks, IT applications, industrial automation, and all critical systems in general.

Dedicated to professional users

Characteristics

The world's first continuous benzene monitor

- microprocessor control to ensure high reliability

- operating economy thanks to high efficiency and different operating modes

- filtered, stabilized, reliable voltage with double conversion On Line technology

- high overloads (up to 150%)

- customizable output voltage

- possibility of programming automatic restart when the mains power returns

- Input power factor control for a sinusoidal absorbed current in phase with the line voltage resulting in low impact on the network

- possibility of modifying the operating parameters via software

- User-activated battery capacity test to ensure long-term functionality and high reliability

- Wide input voltage tolerance. This feature is very important because it allows you to limit battery use to situations of actual power failure.

- possibility of modifying the operating parameters via software

- possibility of remote control of the operating status

- possibility of programming the on and off sequences on a weekly basis

- reduced noise thanks to the use of high-frequency devices and fan speed control

- possibility of connection to both single-phase and three-phase networks (UPH models)

- possibility of paralleling up to 8 units for redundant and/or power parallel (UPH and UPG models)

Mode of operation

MINIPOWER STEROPOWER

- Application sectors

Electronic and electromechanical network stabilizers and conditioners:

- Production lines;

- Machine tools;

- Food industry, bottling, filling, packaging;

- Industrial systems and applications;

- Radio and television transmitters;

- Laser cutting machines;

Electromedical instruments; - Laboratories and test benches;

- Oil and gas plants.

Electrical voltage anomalies in industrial plants

Voltage variation

Because they are subject to constant load variations, distribution lines cannot guarantee a constant voltage. Therefore, electrical equipment usually functions correctly with tolerances of at least +/- 5% from the nominal value. In fact, electricity producers “contractually” specify a variation of +/- 10%. This limit, however, is often exceeded due to “slow variations” (voltage drops caused by undersized lines and overloads), “overvoltages” (significant increases in the RMS value of the line voltage that occur when industries do not absorb power), and “rapid variations” (drops caused, for example, by the activation of utilities such as discharge lamps, spot welders, large electric motors, etc.).

Voltage spikes

These are very short-duration pulsed disturbances that are dangerous for the most susceptible users because they reach voltages of thousands of volts. They are caused not only by switching on high-voltage lines, insertion of power factor correction capacitors, lightning strikes, and the disconnection of loads with high reactive power, but also by low-power loads such as photocopiers and air conditioners connected to the same line that supplies the susceptible users. Due to their short duration, they are not detectable with a standard voltmeter; they are a major cause of failures and service disruptions.

High frequency disturbances

They are very common and easily noticeable by anyone watching television. They cause the snow effect and the annoying streaks that sometimes appear on the screen. They are caused by the sparks generated by electric commutator motors, the “corona discharge” on high-voltage lines, the starters of neon signs and burners, and the magnetic fields radiated by radio and television broadcasters. Line noise, also known as HF NOISE, does not cause problems for electromechanical devices, but is often harmful to electronic equipment.

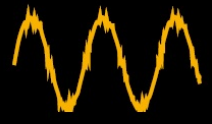

Harmonic distortions

They are caused by the ever-increasing use of electrical devices with non-linear absorption, such as rectifiers, variable speed drives, drives, and switching power supplies. This defect leads to overloads on lines and transformers, burst power factor correction capacitors, incorrect indications from measuring instruments, and generally to the malfunction of any electrical equipment.

Solution

To resolve these issues related to the quality of the electricity supply, upstream equipment is required. We can recommend the right equipment based on the power requirements of your industrial/laboratory/office system and the anomalies encountered on your network.

- Certifications

IREM has obtained quality system certification in compliance with the UNI EN ISO 9001 standard since 1993, confirming its ability to ensure:

- Consistent product quality,

- Guarantee of a reliable product over time,

- Precision and repeatability of all processes,

- Elimination of customer acceptance checks,

- Guaranteed identification and traceability over time.

In 2000, IREM obtained certification for its environmental management system in accordance with the UNI EN ISO 14001 standard.

This certification represents concrete confirmation of the company’s commitment to protecting the environment not only through its products but also through specific behavioral choices.

Since 2004, obtaining certification for its financial statements in accordance with international statutory auditing standards has been a significant annual milestone aimed at maintaining guidelines for transparency and clarity towards third parties. In 2014, the company’s management system obtained certification for compliance with the BS OHSAS 18001 standard, which covers occupational health and safety requirements. This certification demonstrates that worker health and safety are a corporate priority.