KISTLER

KISTLER

The company

The Kistler Group produces both complex measurement systems for research and development and assembly measurement systems that ensure high production quality, offering a wide range of sensor types. It also offers complete acquisition systems for a wide variety of assembly, testing, and development tasks, high-quality tools for tightening, component analysis, and calibration benches for torque wrenches and screwdrivers.

- Electric presses for joining and assembly;

- Rotary (strain gauge) and static (piezoelectric) shaft and flange torque transducers;

- Measurement and acquisition of piezoelectric force transducers and strain gauges (load cells);

- Piezoelectric strain transducers;

- Control electronics; x/y curve monitoring; torque/angle.

SECTIONS:

- Products

ELECTRIC PRESSES AND ASSEMBLY SYSTEMS (PROCESS)

Kistler electric presses and assembly systems are designed for precise joining and pressing, offering complete control of the force/displacement process. This translates into higher finished product quality, operational reliability, and optimized profitability.

Among the main advantages:

Lack of hydraulic oil → maximum cleanliness

Quick and compact installation → less clutter

Reduction of assembly and maintenance costs

High energy efficiency

Kistler offers a broad and modular range, designed for specific and diverse industrial applications. The presses are divided into different families, each with unique characteristics:

Types of electric presses

NCFT

Compact presses with integrated force sensor (0.05–1.5 kN), ideal for cleanrooms and medical applications.

They support wireless transmission for high-precision measurements.

NCFH

Designed for environments where space is limited, thanks to the hollow shaft motor and integrated piezoelectric sensor.

Available in two sizes, with forces from 1 to 60 kN. Perfect for high-speed dynamic joints.

NCFS

With a slim design and piezoelectric sensor, they offer measuring ranges of 15 and 25 kN.

Optimized for automated systems and limited spaces, they guarantee precision and structural rigidity.

NCFS tipo 2152B

Reinforced structure, integrated piezoelectric sensor for tension and compression work.

Compact design ideal for driving stations with narrow center distances.

NCFE

Compression-only models, with force ranges from 2 to 80 kN. Simple and reliable, suitable for a variety of applications.

NCFN

Strain gage technology, available in versions from 30 to 300 kN.

Versatile: suitable for both manual and automated lines. Available with safety brake and customizable design.

NCFC mod. 2163A

Lightweight and balanced presses, ideal for robotics and mobile applications.

Nominal forces: 55 kN (size 1) and 80 kN (size 2), with integrated strain gauge sensor.

NCFR

Designed for processes that combine linear joining and rotational movements, with high precision and control.

Kistler presses

NCFT electric press model 2157 B

Designed for tension and compression, this piezoelectric press covers a measurement range from 0.05 to 1.5 kN.

It is ideal for controlled-force applications in low-intensity joining and assembly processes, both in automated systems and manual workstations.

It is also used in the production and testing of components in the medical sector and in precision micro-production.

It offers maximum accuracy thanks to the integrated piezoelectric sensor, stable wireless transmission, and excellent overload protection, perfect for safely managing delicate and highly sensitive processes.

NCFH electric press model 2151 B

Equipped with piezoelectric technology for traction and compression applications, the NCFH electric press is available in two sizes:

Size 1: range from 1 kN to 15 kN

Size 2: range from 15 kN to 60 kN

Designed for force/displacement-controlled processes, it is ideal for dynamic joints and assemblies.

The integrated hollow shaft motor makes it extremely compact, optimizing space and improving dynamic performance.

The piezoelectric force sensor ensures high precision, with extensive overload protection.

It can be installed both horizontally and vertically, flexibly adapting to different system configurations.

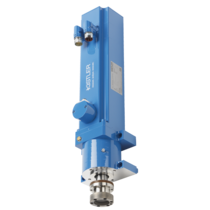

NCFS electric press model 2152 B

This electric press operates in tension and compression with piezoelectric technology and is available with two measurement ranges: 15 kN and 25 kN.

Its slim and compact trapezoidal design makes it ideal for integration into small operating spaces.

Process accuracy is ensured by an integrated linear guide system, while the built-in piezoelectric sensor ensures precise and reliable performance in both horizontal and vertical mounting configurations.

Designed for use in automated production systems, it is a versatile solution for high-precision processes in complex manufacturing environments.

NCFN electric press model 2153 A

This electric press, designed for tension and compression, uses strain gauge technology and offers a wide measurement range from 30 kN to 300 kN, ideal for applications requiring force/displacement monitoring in manual workstations or automated systems.

Its modular design allows for integration even in complex environments, such as where a high operating range is required.

It is equipped with a safety brake that allows for precise control of force and speed, ensuring repeatability, linearity, and process safety.

Furthermore, thanks to the active deflection compensation system, it ensures highly accurate positioning, with high overload tolerance and an intuitive user interface.

It can be installed vertically or horizontally, flexibly adapting to both manual workstations and automated production lines.

NCFE electric press model 2162 A

Electric compression-only press with piezoelectric technology, available in three sizes ranging from 2 kN to 80 kN.

A reliable and cost-effective solution, designed for standard joining and assembly processes.

It offers high movement speed:

Up to 250 mm/s for the 10, 20, and 40 kN versions

200 mm/s for the 80 kN model

With a maximum travel of 350 mm, it guarantees versatility and optimized cycle times.

Installable both horizontally and vertically, it can be easily integrated into machines and production systems.

Pressa elettrica NCFS modello 2152 B

I

The NCFS Type 2152 B joining module features a robust construction with an integrated piezoelectric force sensor, designed for precise measurements in low-force assembly applications.

It covers two measuring ranges, 15 kN and 25 kN, with a useful stroke of 350 mm.

Designed for integration into automated production systems, it stands out for its compact design that allows for short spacing between workstations, optimizing space.

Installation is possible in both vertical and horizontal positions, with flange mounting directly on the machine frame.

The drive pin features threaded holes sized according to the load, for secure and stable tool attachment.

.

NCFC electric press model 2163 A

Perfectly integrated into automated assembly lines, the NCFC joining module stands out for its compact and lightweight design, making it ideal for robotic arm applications, such as clinching and riveting.

The structure is optimized for wall mounting, allowing for simple and stable attachment to machine frames or robots in highly dynamic production environments.

NCFR electric press model 2161 A

Designed for tension and compression, this press is ideal for joining processes combined with rotational movements.

It offers two measurement ranges: up to 15 kN for compression and up to 5 kN for rotation.

With a movement speed of up to 400 mm/s and a maximum stroke of 400 mm, it guarantees high performance in highly dynamic cycles.

The compact design integrates two independent motors, allowing for separate control of compression and rotation.

Sturdy, lightweight, and highly responsive, it is the ideal solution for applications where precision, speed, and flexibility are essential.

Monitoring systems and accessories

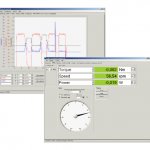

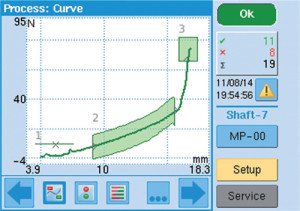

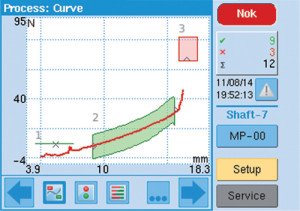

New Maximos NC monitoring system

To provide advanced visualization of joining and assembly processes, Kistler has developed the new Maximos NC monitoring system, which complements the XY Monitoring range with advanced features and a simplified user experience.

Maximos NC stands out for its rapid commissioning times, an intuitive interface, and optimized communication thanks to native fieldbus integration.

A single centralized display can manage up to eight press-fit control devices, reducing system costs and simplifying plant architecture.

Key benefits include:

Rapid response to sudden stops

Flexible control sequence management

High performance in highly dynamic environments

Servo amplifier

Each press requires a dedicated servo amplifier module, compatible with the specific application and model.

The communication interface is based on SERCOS III, with control voltages from 19 to 28 V and a 400 V three-phase power connection.

The system is fully integrated with MaXYmos NC modules and can be managed easily and reliably via Ethernet.

TORQUE MEASUREMENTS: ROTARY TORQUE METER AND PIEZOELECTRIC STATIC TORQUE METER

The torque transducer is an essential measuring instrument for detecting mechanical torque, a crucial parameter in numerous industrial applications.

Precise torque measurement, especially on rotating parts, is essential for optimizing the performance of motors and engines and ensuring accurate control of production processes.

The Kistler range offers a comprehensive selection of shaft, flange, and non-rotating torque transducers, designed to also detect reaction torque, ensuring reliability and precision in any application context.

Torque Meter 4501A

With an accuracy of 0.2% and no built-in amplification, this torque transducer is particularly suitable for high-precision assembly and screwdriving operations.

The measurement signals are transmitted via a slip ring and brush system, compatible with all strain gauge bridge amplifiers on the market.

The cylindrical shaft ends allow for a backlash-free friction fit, ensuring stability and repeatability.

Designed to measure torque in both directions of rotation, it combines a robust design with compact, easy-to-handle dimensions, making it ideal even in limited spaces.

It is resistant to high acceleration, with a maximum speed of up to 3,000 rpm.

The universal versions with rounded shafts are perfect for low-speed applications or intermittent measurements.

Torque Meter 4502A

With an accuracy of 0.2% and integrated electronics, this amplified torque transducer is ideal for static and dynamic torque measurement.

Compatible with both manual and monitored screwdrivers, it is used to monitor speed and rotation angle, proving particularly effective in production process monitoring and quality control activities.

The compact design makes it easy to install even in small spaces, while the variety of available shaft interfaces allows for integration into a variety of application configurations.

Torque Meter 4520A

With an accuracy of 0.5% and integrated amplification, this torque sensor is a cost-effective solution that is easy to install and use.

Contactless signal transmission and cylindrical shaft ends facilitate integration into existing systems.

Thanks to its compact and robust design, it is suitable for static and dynamic torque measurement in assembly, quality control, and laboratory testing applications.

Ideal for continuous use in production environments, it can be connected directly to a PLC, ensuring reliable, real-time monitoring throughout the line.

Torque Meter 4503B

With extremely high accuracy (0.05% – 0.1%) and integrated amplification, this torque transducer is designed to ensure extremely precise measurement performance.

The digital conditioning system allows for both digital and analog output, offering maximum integration flexibility.

Thanks to the dual-range sensor and integrated measurement electronics, it ensures rapid response even at very high speeds, with a resolution of up to 8,192 pulses per rotation.

It is the ideal solution for laboratory, production, and quality control applications, where data accuracy and reliability are critical.

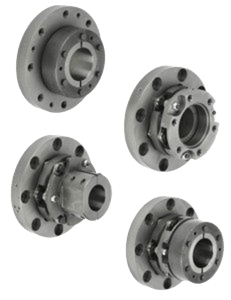

COUPLING JOINTS for Shaft Torque Meters

Couplings are essential accessories for ensuring maximum torque transducer performance.

They compensate for parasitic loads generated by mechanical misalignments, helping to maintain system integrity.

To ensure high measurement accuracy even under challenging conditions, Kistler offers a range of couplings specifically designed to accommodate various installation configurations.

In addition to improving transducer accuracy, these couplings protect connected components from wear, extending the life and reliability of the entire system.

Model 2301A Coupling for Shaft Torque Meter

With an accuracy of 0.2% and no amplitude, this coupling is particularly suitable for high-precision assembly and tightening applications.

Made of stainless steel, it installs in-line on both sides of the torque sensor.

Thanks to its low moment of inertia and compact design, it requires little space and minimal maintenance.

Its direct integration with the torque sensor allows for compensation for driveline misalignments, eliminating parasitic loads and reducing the risk of sensor damage, improving accuracy and operating life.

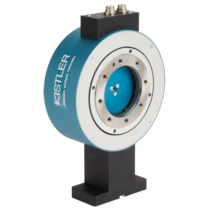

FLANGE TORQUE METER

Flange-mounted rotary torque transducers with strain gauge technology are the ideal solution where space is limited, thanks to their compact design and ease of installation.

These models allow for the integration of couplings, useful for safely and precisely connecting the main shaft to the sensor, and then the sensor to the application.

The following models fall into this category:

Torque Meter 4510B

Flange torque transducer with 0.2% accuracy and dual measuring range, featuring a robust strain gauge flange for precise torque measurement.

The model integrates a speed sensor, while a switchable measuring range is available as an option.

With the included shaft-hub mounting kit, the 4510B model can be connected directly to the crankshaft.

It is ideal for applications on combustion engines, electric motors, gearboxes, rollers, and test benches, offering reliability and flexibility in test and production environments.

Coupling joints for 4510 sensors

The 2304A coupling, made entirely of steel, is specifically designed for use with 4510 Series torque transducers.

It can be bolted directly onto the torque transducer and is available in various mounting configurations to suit various application needs.

Extremely resistant to high torques and completely maintenance-free, it represents a reliable and durable solution for high-performance industrial applications.

Flange Torque Transducer (ROTOR) 4550 A - Flange Torque Transducer (ROTOR) 4551 A

With an accuracy of 0.05%, this flange torque transducer confirms the excellent performance of the range, offering extremely precise measurements even at high rotational speeds.

Based on strain gauge technology, it requires use in conjunction with a stator.

It is a robust and reliable solution, ideal for high-performance test benches such as those for racing engines or turboprops.

The compact design allows for use in confined spaces, while the optimized mass reduces dynamic moments during acceleration and braking, improving measurement stability.

The system provides contactless transmission of analog and digital signals to the acquisition unit, which features three outputs and an integrated switchable measuring range.

Easy to configure and install, this torque transducer significantly reduces operating time and costs, making it ideal for standard test applications and advanced industrial testing.

Stators 4541A and 4542A

Designed to ensure high torsional strength, these couplings combine compactness and operational reliability.

They must be mounted directly on the unit being measured and are completely wear- and maintenance-free.

Thanks to their design, they can compensate for axial, radial, and angular misalignments, preventing measurement errors and protecting the sensor from damaging stresses.

2305A Couplings for 4550 Flange Torque Transducer and 2300A Couplings for 4551 Flange Torque Transducer

Designed to ensure high torsional strength, these couplings combine compactness and operational reliability.

They must be mounted directly on the unit being measured and are completely wear- and maintenance-free.

Thanks to their design, they can compensate for axial, radial, and angular misalignments, preventing measurement errors and protecting the sensor from damaging stresses.

MULTICOMPONENT TORQUE AND FORCE SENSORS

Multicomponent torque and force sensors feature pairs of longitudinally cut quartz rings that measure the force acting on the sensor. Each pair of rings measures one of two shear components: longitudinal shear and transverse shear. These sensors are typically mounted in groups of three or four and are suitable for both three-component force measurement and six-component torque measurement.

REACTION TORQUE METER

Static reaction torque transducers are easy to install and ideal for quick and precise torque measurement.

They can detect even minimal displacements on the sensor axis, in both directions of rotation.

Thanks to their high dynamic range and wide bandwidth, they are effective even under quasi-static conditions (fractions of a Hertz).

They are particularly suitable for:

– Torque adjustment and control

– Calibration of torque wrenches

– Measurements on clutches and electric motors

– Testing of rotary switches and measurement systems

The following Kistler models fall into this category:

Torque transducers 9329A, 9339A, 9349A, 9369A, 9389A

Featuring a compact design and high mechanical adaptability, these sensors are ready for reaction torque transducer mounting, simplifying integration into test systems.

They cover a wide measurement range, from ±1 N m to ±1,000 N m, and are ideal for measuring shaft torque in:

- Spring torsion testing

- Electric motor and clutch testing

- Rotary testing and dynamometer testing

All models are pre-loaded and calibratable, ensuring high reliability and accuracy.

Torque transducers 9345B and 9365B

These reaction torque sensors enable the simultaneous measurement of two force components: tensile and compressive, in the torque range of ±20 kN and ±200 N m.

They are particularly suitable for applications requiring analysis of the correlation between axial force and torque, such as:

– Puncture and breakage tests on printed circuit boards (PCBs)

– Tightening torque measurement

– Control of screwdriving processes and other dual-stress mechanical operations

Designed to offer precision and reliability even in complex tests, they are ideal for research, development, and industrial production environments.

Accessories and complements

“Sensor Tool” 4706A

The “Sensor Tool” 4706A control software allows the display and setting of instrument parameters from a PC, display of both numerical and graphic data, definition of the pulse output speed, calibration of the instruments and data storage.

FORCE MEASUREMENTS: PIEZOELECTRIC LOAD CELLS

In recent years, force transducers have reached a high technical standard. Transducers achieve part of their high accuracy thanks to improved calibration options. The measurement accuracy of a force transducer depends largely on the installation conditions. Unfavorable installation conditions not only negatively impact measurement accuracy, but also the dynamic properties of the measuring chain and immunity to electromagnetic fields.

Learn more

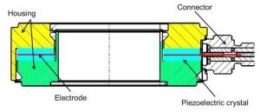

Piezoelectric sensors consist of two crystal discs with a foil electrode in between. When force is applied, an electric charge is generated that can be measured by a charge amplifier. The charge is proportional to the applied force. Due to their operating principle, these sensors have a drift of 1 N/minute while the measuring chain is in operation. They exhibit very small deflections when force is applied, thus offering high rigidity. This results in a high resonance frequency which, in principle, is very favorable for dynamic or quasi-static applications. Further advantages of these sensors include a wide operating temperature range (-196°C; +700°C) and easy signal summation for sensors mounted in parallel. All transducers are made of stainless steel and are suitable for use in harsh industrial environments with stringent operating requirements. They are maintenance-free and can be installed in places that are difficult to access. Another significant feature of piezoelectric technology, given its high precision, is the ability to calibrate and program different measurement ranges. This avoids splitting, meaning using a single sensor instead of two or more sensors with different measurement ranges, ensuring the most suitable full scale, simply by using a charge amplifier.

These sensors can be calibrated or pre-calibrated. Force washers can be used on both bolts and screws, so the inside diameter of the force washers usually corresponds to the outside diameter of metric threads. The resulting force from the bolt or screw on which the force washer is used acts as a parallel spring element, thus reducing the system’s sensitivity. In this case, a value of approximately 10% should be expected. Calibrated force washers cannot be factory-calibrated, and calibration is always essential. To ensure good reproducibility, it is essential that the force washer be preloaded. The amount of preload depends on the nominal force of the sensor and the force to be measured; when the washer is preloaded to 50%, it can withstand the maximum bending moments. Ideally, the preload should be such that the sum of the preload force and the operating force is on average 50% of the nominal force of the washer. This recommendation is particularly important for piezoelectric force washers. Calibrated force washers (load washers) have a high degree of protection and are supplied ready for assembly, offering the same advantages as strain transducers in this respect; therefore, preloaded and calibrated ones are preferable to uncalibrated ones. Furthermore, as with other piezoelectric transducers, force washers offer sufficient sensitivity to be virtually independent of their nominal force.

The models

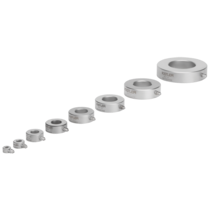

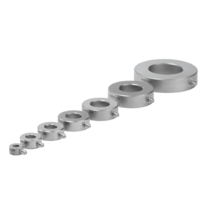

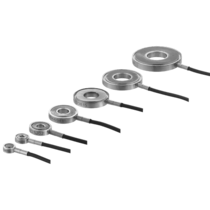

Piezoelectric load cells 9001C, 9011C, 9021C, 9031C, 9041C, 9051C, 9061C, 9071C, 9081C, 9091C

The 9001C, 9011C, 9021C, 9031C, 9041C, 9051C, 9061C, 9071C, 9081C, and 9091C (load washer) piezoelectric load cells, from 7.5Kn to 1200Kn, for tension and compression, for calibration, offer a wide measurement range with broadband, high rigidity, a compact design and accessories for correct mounting. This type of cell with dual scale preload is particularly ideal for materials testing, testing machines, impact measurement, tightening screws and punching.

Piezoelectric Load Cells 9101C, 9102A, 9103A, 9104A, 9105A, 9106A, 9107A

The 9101C, 9102A, 9103A, 9104A, 9105A, 9106A, and 9107A piezoelectric load cells (load washers), 0-20Kn and 0-700Kn, for calibration, offer a wide measurement range, high rigidity, and a compact design. These instruments are used in industrial control and monitoring functions.

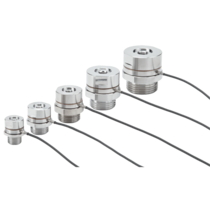

Piezoelectric Load Cells 9130B, 9131B, 9132B, 9133B, 9134B, 9134B, 9136B, 9137B

The 9130B, 9131B, 9132B, 9133B, 9134B, 9136B, and 9137B piezoelectric load cells, tensile and compressive, ranging from 3 to 80 kN, requiring calibration, have a particularly slim design that allows them to be mounted even in very small spaces, while also offering high rigidity and an integrated connection cable. These cells are used as monitoring instruments, for punching forces, and for measuring large forces.

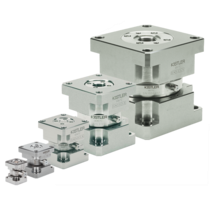

Piezoelectric load cells 9173B, 9174B, 9175B, 9176B, 9177B

The 9173B, 9174B, 9175B, 9176B, and 9177B piezoelectric load cells, calibrated and preloaded in tension and compression up to 75 kN, offer high rigidity, a very flat and compact design, and an integrated cable. They are used for force measurement in robotic systems, for monitoring presses, punching machines, clamping processes, and joining.

9313AA1 and 9313AA2 Piezoelectric Load Cells

The calibrated and preloaded 9313AA1 and 9313AA2 compression-only piezoelectric load cells feature a compact design and are ready for installation thanks to their flexible mounting and central bore. They are ideal for sensor process monitoring, compressive force measurement on presses, and test equipment.

Piezoelectric Load Cells 9323AA, 9323AA-9323A-9333A-9343A-9363A-9383A

The 9323AAA, 9323AA-9323A-9333A-9343A-9363A-9383A piezoelectric load cells, calibrated and pre-loaded with compression only, 0-5Kn and 0-20Kn, have a compact design and are ready for mounting thanks to their flexible adaptation and central hole. They are ideal for process monitoring sensors, for measuring compressive force on presses, and for test equipment.

Piezoelectric Load Cells 9301C, 9311C, 9321C, 9331C, 9341C, 9351C, 9361C, 9371C

The 9301C, 9311C, 9321C, 9331C, 9341C, 9351C, 9361C, and 9371C piezoelectric load cells, calibrated and preloaded in tension and compression, from 3 kN to 160 kN, are easily installed thanks to the centering mounting. They can be used to measure impact forces, shock loads, impact testing, quality control, and assembly machine monitoring.

Piezoelectric load cells 9340A, 9819A

The 9340A…9819A piezoelectric load cell, calibrated up to 60 kN, was specifically designed for manually and pneumatically operated presses. It offers great flexibility. It is suitable for press-fitting, snap-fitting, chamfering, inserting, closing, probing, and riveting processes.

Piezoelectric load cells 9203

The 9203 piezoelectric load cell, calibrated, preloaded, tension and compression, and for small forces, is highly sensitive. It features an extremely low measurement threshold, high frequency, and compact size. It is ideal for measuring contact forces and for extraction and assembly in automatic machines.

Piezoelectric load cells 9205

The calibrated, preloaded, high-sensitivity 9205 piezoelectric load cell, suitable for tension and compression, is suitable for small forces ranging from 0.5 N to 500 N and features an extremely low measurement threshold, high frequency, and compact size. It is ideal for measuring contact forces, as well as for extraction and assembly in automatic machinery.

Piezoelectric load cells 9207

The calibrated, pre-loaded 9207 piezoelectric load cell, rated for 0.5N to 500N of tension and compression, is highly sensitive and suitable for small forces. It features an extremely low measurement threshold, high frequency, and compact size. It is ideal for measuring contact forces, and for extraction and assembly in automatic machines.

Piezoelectric load cells 9217

The calibrated, preloaded 9217 piezoelectric load cell, capable of tensile and compressive forces from 0.5 to 500 N, is highly sensitive and suitable for small forces. It features high rigidity and very low transverse sensitivity. It can be used for a wide range of applications, such as on-product testing (keyboards, switches, connectors, springs), as well as for general use, such as force measurement in research and development.

Piezoelectric load cells 9215, 9215

The calibrated, pre-loaded, compression-only 9215A piezoelectric load cell, 0.5 to 500N, is a high-sensitivity, small-force, high-sensitivity load cell featuring high rigidity and low transverse sensitivity. Its small size makes it ideal for mounting in confined spaces. It can be used in a variety of applications directly on the test product, as well as in research and development.

TRIAXIAL LOAD CELLS

Triaxial piezoelectric load cells are sensors capable of measuring dynamic or quasi-static force in the three directions x, y, and z. They are characterized by extremely precise measurement regardless of the point of force application, a wide usable frequency range, and a compact design. These sensors are used to measure shear force during machining, impact forces in crash tests, frictional forces and vibrations, as well as forces acting directly on products.

9017C Piezoelectric Load Cells

The 9017C, 9018C, and 9016CA multicomponent, triaxial piezoelectric load cells offer precise measurement regardless of the force application point, a wide frequency range, and exceptional ease of assembly and installation. They feature a highly robust multipole connector. They are particularly suitable for measuring process forces during manufacturing, measuring friction forces for product testing, measuring vibration forces on aerospace components, and measuring impact forces in crash tests and on test benches.

9027C Piezoelectric Load Cells

The 9027C multicomponent, calibratable, triaxial piezoelectric load cell offers precise measurement regardless of the force application point, a wide frequency range, and exceptional ease of assembly and installation. A highly robust multi-pin connector is already integrated. It is particularly suitable for measuring process forces during manufacturing, measuring friction forces for product testing, measuring vibration forces on aerospace components, and measuring impact forces in crash tests and on test benches.

9067C Piezoelectric Load Cell

The 9067C multicomponent, calibratable, triaxial piezoelectric load cell offers precise measurement regardless of the force application point, a wide frequency range, and exceptional ease of assembly and installation. A highly robust multi-pin connector is already integrated. Three sensors measure forces in various applications: shear during machining, impact forces in crash tests, vibration forces on aerospace components, friction forces, and forces applied directly to the product.

9077C Piezoelectric Load Cell

The 9077C multicomponent, calibratable, triaxial piezoelectric load cell offers precise measurement regardless of the force application point, a wide frequency range, and exceptional ease of assembly and installation. A highly robust multi-pin connector is already integrated. Three sensors measure forces in various applications: shear during machining, impact forces in crash tests, vibration forces on aerospace components, friction forces, and forces applied directly to the product. Request technical documents for this model.

Piezoelectric Load Cells 9317C, 9327C, 9347C, 9367C, 9377C

The 9317C, 9327C, 9347C, 9367C, and 9377C multicomponent, calibrated, pre-loaded, triaxial piezoelectric load cells are ready for installation and feature three measuring components, enabling high precision regardless of the force application point. They offer a wide frequency range and a robust multi-pin connector is already integrated. They differ in their ranges. Three sensors measure forces in various applications: shear during machining, impact forces in crash tests, vibration forces on aerospace components, friction forces, and forces applied directly to the product.

FORCE MEASUREMENTS: STRAIN GAGE LOAD CELLS

Strain gauge load cells always include a spring element to which force is applied. This force causes the spring element to deform slightly. Strain gauges installed at appropriate locations are stretched or shortened, thereby changing their resistance. At least four strain gauges are connected together to form a Wheatstone bridge circuit. By supplying a voltage to the measuring bridge, the resulting output voltage is proportional to the applied force. Strain gauge-based sensors exhibit virtually no drift and are therefore particularly suitable for static long-term monitoring tasks, such as weighing. In principle, small-force transducers are soft spring elements, and the transducers’ resonant frequency is correspondingly low. These sensors enable highly precise static calibration, and the spring elements can be designed for optimal reproducibility.

4576A strain gauge load cell, tension and compression

The 9017C, 9018C, and 9016CA multicomponent, triaxial piezoelectric load cells offer precise measurement regardless of the force application point, a wide frequency range, and exceptional ease of assembly and installation. They feature a highly robust multipole connector. They are particularly suitable for measuring process forces during manufacturing, measuring friction forces for product testing, measuring vibration forces on aerospace components, and measuring impact forces in crash tests and on test benches.

4577A strain gauge load cell, compression only

The 4577A compression-only strain gauge load cell, from 0.1kN to 200kN, has a robust, flat, and compact design. The load force must be applied concentrically, thus avoiding transverse forces, and the cell must be installed on a flat, perfectly smooth surface to avoid distortions in load measurements. It is an economical solution that can be used for force control in joining operations, for measuring static and dynamic compressive forces, and on production lines. It is also resistant to corrosive industrial environments.

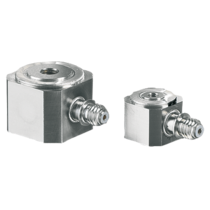

4578A strain gauge load cells, tension and compression

The 4578A strain gauge load cells, for tension and compression, have a robust and compact design. This cell has a measuring range from 0-0.1 kN to 0-10 kN. The load force must be applied centrally, thus avoiding torsion or transverse forces. To function properly, the cells must be mounted on smooth and perfectly flat surfaces. They are suitable for static, quasi-static, and dynamic measurements, such as measuring and monitoring forces in assembly processes.

4579A strain gauge load cells, tension and compression

The 9077C multicomponent, calibratable, triaxial piezoelectric load cell offers precise measurement regardless of the force application point, a wide frequency range, and exceptional ease of assembly and installation. A highly robust multi-pin connector is already integrated. Three sensors measure forces in various applications: shear during machining, impact forces in crash tests, vibration forces on aerospace components, friction forces, and forces applied directly to the product. Request technical documents for this model.

Portable Device Model 4703B

The Model 4703B portable force measuring device is used for strain gauge load cell force measurements. It features a backlit, easy-to-read display. Buttons on the front of the unit provide access to all important functions (calibration, minimum/maximum display, and quick range selection).

FORCE MEASUREMENTS: SHEAR AND DEFORMATION

Piezoelectric shear load cells are quartz sensors with an extremely flat design, capable of measuring dynamic and quasi-static shear forces. Characterized by extremely small dimensions, high rigidity, and maximum resolution, they are ideal for installation in mechanical structures with limited space.

Piezoelectric strain load cells are particularly sensitive sensors, also suitable for measurements on moving parts. They are suitable for indirect force measurement on mechanical presses, machine tools, high-speed production machinery, or assembly units.

Piezoelectric shear beam load cells 9143B, 9144B, 9145B, 9146B, 9147B

The 9143B, 9144B, 9145B, 9146B, and 9147B piezoelectric load cells measure shear force and, thanks to their very compact design, are easily installed in limited spaces. Characterized by high rigidity, they already have an integrated connection cable. They are ideal for monitoring shear forces in machines and assembly processes.

9232A Piezoelectric Strain Load Cells

The 9232A piezoelectric load cell is a highly sensitive strain transducer designed for applications where strain gauge transducers reach their dimensional limits or have low sensitivity. It has a very compact design and is mounted with a single screw. It detects even very small deformations, converting them into proportional signals. With proper calibration, this cell can also be used to determine the active force. Insensitive to electromagnetic fields, it is ideally suited for applications on cable manufacturing machines, presses, or welding machines.

9241C Load Cells

The preloaded 9241C load cell measures compressive and tensile forces. It can be mounted transversely or longitudinally in a hole drilled directly into the machine structure. The connection cable is already integrated, making installation simple.

9243C load cell

The 9243C preloaded tension and compression load cell can indirectly measure forces of various magnitudes. It can be mounted transversely or longitudinally in a hole drilled directly into the machine structure. It is suitable for monitoring injection molding machines, industrial process control, and machine tools.

ANALYSIS: PROCESS MONITORING INSTRUMENTATION

MaXYmos is a next-generation monitoring tool that allows you to visualize and evaluate joining and press-fitting processes. They are designed for measuring, monitoring, and testing processes, as well as for product and material testing. They enable the rapid elimination of process waste, improving product and process quality.

MaXYmos can therefore be used to monitor Force/Displacement; Torque/Angle; Pressure/Time; Force/Torque in complex applications in product assembly and testing. Thanks to powerful evaluation techniques, a wide selection of connectable sensors, and an unlimited choice of fieldbus types, it offers a series of useful process monitoring functions that guarantee 100% quality in testing and assembly.

MaXYmos BL

This model’s monitor features two interconnected XY channels that evaluate the generated curve using universal evaluation elements. Despite its affordable price, the user has everything they need to view the resulting data: a historical curve memory for NOK diagnosis, a process value table, a Fieldbus interface for data exchange, and an Ethernet interface for rapid data export and remote maintenance.

MaXYmos TL

This is Kistler’s latest addition. It can be expanded up to 8 pairs of XY channels and features a large 10.4″ touchscreen with very high resolution. It is ideal for users with specific and sophisticated needs. This model meets all possible requirements in terms of application management, ease of use, and flexibility. It is equipped with a series of evaluation elements for monitoring even very complex XY curves; these instruments provide real-time feedback, allowing them to be used for rapid interventions and rapid diagnoses, thanks also to remote internet connection.

Additional Information

Both versions are used for monitoring and archiving data for:

- Bearing installation;

- Crankshaft installation;

- Riveting;

- Screw tightening torque measurement;

- Force/torque quality testing on linear or rotary components

Accessories and complements

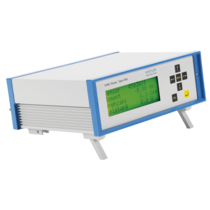

CoMo Torque 4700 B

The CoMo Torque 4700 B is a universal measuring amplifier suitable for evaluating torque sensors (torque transducers). Torque/speed and torque/angle measurements can be evaluated. Mechanical performance is calculated and then displayed on the device. The CoMo Torque is also equipped with digital inputs and outputs. It can record extreme values and save measurement curves. It is ideal for factory instrumentation and laboratories.

Sensor Tool 4706A Acquisition Software

The Sensor Tool 4706A acquisition software connects the sensor and control unit to the PC. Instrument settings and configurations can be modified using this software. Sensor data can be analyzed and evaluated using various interfaces for data visualization and export.

AMPLIFICATION: PIEZOELECTRIC AND STRAIN GAUGE SIGNALS

Signal amplification is essential for measuring mechanical quantities such as force, strain, or torque. Charge amplifiers convert the output signal from a piezoelectric sensor to a proportional voltage. These voltage signals are then also used as input variables for monitoring and control processes. To meet industrial needs, Kistler offers a wide range of amplifiers with different designs, number of measurement channels, accuracy, measuring ranges, sensitivity, bandwidth, filter characteristics, and signal scaling and processing options.

Charge Amplifier Model 5015 A

The Model 5015 A charge amplifier is suitable for laboratory use. It features an LCD display and a user-friendly menu. It has an adjustable measuring range and high and low filters. It can indicate overload and can be digitally controlled via a remote input.

Charge Amplifier Model 5171 A

The Model 5171A charge amplifier is universal and innovative, reducing wiring for a simpler measurement chain and can be used anywhere mechanical quantities are measured by piezoelectric sensors. Piezoelectric sensors produce an electrical charge that varies in direct proportion to the load acting on the sensor. The 5171A module converts this charge directly into digital values that can be processed by the National Instruments CompactRIO system.

Charge Amplifier Model 5073 A

The Model 5073 A charge amplifier is suitable for all industrial applications (monitoring, control, and optimization of industrial processes and machinery) thanks to its rugged design. It offers a very wide measurement range, two switchable and independent external measuring ranges, and integral peak memory for each channel. This model is PLC-enabled.

Charge Amplifier Model 5074 B

The 5074B model on EtherCat offers high performance with transmission rates of up to 50 kSps per channel. This enables real-time transmission of measurement data with cycle times of up to 100 μs, allowing even critical process controls to be implemented. No data is permanently stored on the digital amplifier. Combined with integrated electrical isolation, this early digitization enables reliable, interference-resistant transmission of measurement values to the master system. The rugged housing is IP67-rated with FKM/FPM sealing elements.

For strain gauge sensors

Charge Amplifier Model 4701 A

The Model 4701 A charge amplifier is designed for industrial applications thanks to its rugged metal enclosure and panel mount. It is a universal measuring amplifier for strain gauge sensors and torque transducers.

THE POTENTIOMETERS

These are displacement sensors used in conjunction with the Maxymos and the cell to better monitor the process. The potentiometers measure the travel with extreme precision.

Linear Potentiometer 2124A10, 2124A100

It’s a displacement sensor with a return spring and integrated cable. It’s used for process monitoring and is available for measuring strokes from 10 mm to 100 mm.

Linear Potentiometer 2125A25, 2125A150

It’s a spring-loaded displacement sensor with an integrated cable. This potentiometer can be attached to the existing press frame, thus remaining aligned. It’s ideal for process monitoring and can measure strokes from 25 mm to 150 mm.

Linear Potentiometer 2121A75, 2121A750

It’s a displacement sensor with slotted mounting that keeps the potentiometer aligned. It can measure strokes of up to 750 mm. It’s suitable for process monitoring.

Rotary Potentiometer 2123A

It is a displacement sensor capable of continuously measuring a 360° rotation. It is ideal for process monitoring.

- Application sectors

Electric presses, torque meters, force measurement and acquisition:

- Internal combustion engines;

- Electric motors;

- Automotive industry;

- Electrical/electronics industry;

- Mechanical/hydraulic industry;

- Pharmaceutical/cosmetics industry;

- Machine tools;

- Food industry;

- Laboratories and test bench manufacturers;

- Production lines for various sectors.

- Kistler Technologies

Piezoelectric and Strain Gauge Force Transducers

Two operating principles have become dominant in force measurement: piezoelectric force sensors and strain gauge force transducers. Piezoelectric force sensors are active measurement systems, meaning they do not require external energy to function. They consist of two crystal discs with a foil electrode in between. When force is applied, an electric charge is generated that can be measured by a charge amplifier. The charge is proportional to the applied force. Given their operating principle, piezoelectric force sensors have an estimated drift of 1 N/minute while the measuring chain is in operation. Since this value remains unchanged regardless of the measured force, the relative measurement error resulting from the drift is particularly unfavorable when measuring forces over long periods of time.

Piezoelectric sensors exhibit very small deflections when force is applied because they offer high rigidity. This results in a high resonant frequency, which, in principle, is very favorable for dynamic or quasi-static applications. Piezoelectric sensors can be very compact and are therefore the optimal solution when integration into existing systems is required and for rapid measurement of small forces.

Strain gauge force transducers are passive measuring systems, meaning they require external energy to function. They always comprise an elastic element to which force is applied. This force causes a minimal deformation of the elastic element. Strain gauges installed at appropriate points are lengthened or shortened, thereby varying their resistance. At least four strain gauges are connected together to form a Wheatstone bridge circuit. By supplying a voltage to the measuring bridge, the resulting output voltage is proportional to the applied force. These sensors exhibit virtually no drift and are therefore particularly suitable for static long-term monitoring tasks such as weighing. The so-called creep (a reversible, time-dependent change in the output signal that occurs when a constant force is applied) is extremely small, as it can be minimized by appropriately choosing the strain gauge design.