ESPEC

MMM

ESPEC - Climatic Chambers

The first industry was established in Japan under the name "Tabai ESPEC" in 1983 simultaneously with the American branch. The European branch was established on October 1, 2006 in Munich, and now ESPEC is now one of the world's largest climatic chamber manufacturers.

Their mission is to provide the highest quality products for the European market. This industry is connected with other locations in the USA and Japan, as well as sales and support service around the world.

ESPEC 's products range from small desktop thermal and climatic chambers to large thermal chambers that can also test solar panels, auto components ,batteries ,battery chargers ,inverters for electric motors. ESPEC provides the equipment for all your testing needs. Many of the chambers have countless optional features to meet your every need.

Products

PRODUCTS ESPEC: CLIMATIC CHAMBERS

CLIMATE CHAMBERS - THERMAL STRESS TEMPERATURE AND HUMIDITY CONTROL

The SH and SU series are climatic chambers for temperature and humidity testing of environmental resistance in sizes from 20 to 60 liters. These models offer a temperature range from -20°,-40° or -60° up to +150° or 180°C with excellent performance. The chambers all have a user-friendly panel.

Request technical documents for these models

This series of climatic chambers have two sizes of 105 and 206 Liters. They allow remote control via PC or browser and management of different temperature and humidity ranges.

Request technical documents for these models

Request technical documents for these models

The J series offers numerous models in different capacities and features systems with high quality standards and excellent energy efficiency. They have very good heating-cooling and air-conditioning circuits that allow testing in the range of -40° to +180°C. Versions with a glass window, or glass door, are also available.

Request technical documents for these models

ACCELERATED STRESS TEST SYSTEMS

Queste camere sono state costruite per testare componenti elettronici e altri tipi di campioni per la resistenza all’umidità e alle temperature. Questi sistemi forniscono risultati in tempi brevi e offrono prestazioni elevate.

Una caratteristica unica di queste camere è il controllo della temperatura di bulbo umido e asciutto, misurate direttamente in un sensore apposito. Questa funzionalità, conforme con lo standard IEC60068-2-66, permette il controllo accurato dell’umidità durante tutti il processo di test. È possibile impostare una fase di post-test a temperatura controllata costante prima di rimuovere i campioni.

Tutte le impostazioni sono facilmente impostabili dal pannello di controllo, con la possibilità di memorizzare 10 pattern con 30 singoli step per ognuno.

All’interno della camera sono disponibili degli attacchi per l’alimentazione e il controllo dei campioni durante il test.

Ovviamente questi dispositivi hanno tutte le funzionalità per la massima sicurezza e il controllo di sovra riscaldamenti.

Request technical documents for these models

WALK-IN CLIMATIC CHAMBERS - TEMPERATURE AND HUMIDITY

Serie di camere per il controllo della temperatura e dell’umidità da 1000 a 5000 L. Ideali per il test di pannelli solari o campioni di grandi dimensioni.

Questi modelli permettono di testare i campioni su un grande range di temperature, da -70 a +180°C a seconda dei modelli. Sono disponibili versioni con o senza il controllo della temperatura.

La velocità di variazione della temperatura arriva a 3°C al minuto.

Sono possibili diverse personalizzazioni di questo prodotto per soddisfare anche le richieste più esigenti. Ad esempio sono disponibili moduli che permettono variazioni di temperatura fino a 10°C al minuto, maggiorazioni della ventilazione forzata, vetri di ispezioni anche laterali etc..

Request technical documents for these models

Con un sistema speciale per la refrigerazione della camera, questi modelli sono particolarmente efficienti nel consumo di energia.

I modelli di questa serie sono equipaggiati con porte Ethernet per il controllo remoto da PC, tablet o smartphone. È possibile comunicare con la camera attraverso un browser via internet per modificare o anche fermare il processo di test. Tutti i modelli sono disponibili con raffreddamento ad aria o ad acqua.

All models are available in different sizes, volume (floor area):

- Type 1: 4.2 m³ (2.0m²)

- Type 2: 8.1m³ (3.9m²)

- Type 3: 12.5m³ (5.9m²)

- Type 4: 16.8m³ (8.0m²)

- Type 6: 25.8m³ (12.3m²)

- Type 8: 34.8m³ (16.6m²)

- Type 10: 43.8m³ (20.8m²)

- Type 12: 52.7m³ (25.1m²)

Request technical documents for these models

Chambers specifically designed for solar panel testing that allow testing of:

- Thermal Cycle Test (200 cycles between 85°C and -40°C)

- Humidity Freeze Test (10 cycles of hot/humid 85°C 85%rh and -40°C)

- Damp Heat Test (long-term 1000 hours at 85°C 85%rh)

Request technical documents for these models

THERMAL SHOCK - AIR/AIR

Queste camere permettono di effettuare test di shock termici a singola camera. Sensori speciali e algoritmi permettono un massimo risparmio di energia nelle fasi di preriscaldamento e preraffreddamento della camera. Vibrazioni ridotte al minimo per evitare il rischio di scollegamento del campione con i cavi di controllo e potenza.

Queste speciali camere hanno un sistema che evita la formazione di ghiaccio per l’assenza di penetrazioni di aria dall’esterno. Sono possibili fino a 1000 cicli ininterrotti con tempi di esposizione di 15 min.

I sensori di controllo della temperatura sono posizionati sul campione per una massima precisione del test.

Le camere possono essere accoppiate con un sistema di controllo e valutazione computerizzato.

Request technical documents for these models

Le camere delle serie TSD e TSE permettono il movimento del campione da una area calda ad una fredda con un elevatore che lo sposta in 10 secondi. Una speciale attenzione è stata posta nella costruzione dell’elevatore per una minima quantità di vibrazioni durante i movimenti.

I sensori di controllo della temperatura sono posizionati sul campione per una massima precisione del test.

Le grandi capacità delle camere serie TSD (fino a 100L) permettono il test di circuiti stampati di dimensioni A4 appoggiati in orizzontale. Le camere serie TSE (fino a 11L) invece sono studiate per ottimizzare le prestazioni per campioni più piccoli.

Request technical documents for these models

OVENS

Suitable for a wide range of applications, from testing temperature characteristics to heat treatment and drying. Programmed operation now allows storage of ten patterns, each with up to twenty steps. Provides a wide range of functions, including temperature ramp settings and up to 999 repeat cycles.

High-performance chamberA temperature indication controller with advanced PID operation and an originally developed chamber configuration provide high chamber performance. Temperature uniformity, temperature constancy, temperature heating rate, and temperature recovery time are performed with utmost reliability.

Wide choice of modelsThere are 16 ovens available with a combination of temperature ranges, capacities, and instrumentation

A space-saving vertical chamberComponents are incorporated into the top of the vertical chamber. It increases productivity in the production line and saves lab space.

Seamless internal door structureThe back of the door is a unique molded structure that prevents heat loss from loose joints.

Large processing capacityBecause the floor and shelves of the chamber have been significantly reinforced, a large quantity of samples can be loaded and processed at the same time. Sliding shelves ensure easy handling of samples.

Excellent heating performanceHeating performance is greatly improved so that the chamber temperature remains constant even if the ventilation damper is open (at +20°C room temperature).

Request technical documents for these models

Suitable for a wide range of applications, from testing temperature characteristics to heat treatment and drying. Programmed operation now allows storage of ten patterns, each with up to twenty steps. Provides a wide range of functions, including temperature ramp settings and up to 999 repeat cycles.

High-performance chamberA temperature indication controller with advanced PID operation and an originally developed chamber configuration provide high chamber performance. Temperature uniformity, temperature constancy, temperature heating rate, and temperature recovery time are performed with utmost reliability.

Wide choice of modelsThere are 16 ovens available with a combination of temperature ranges, capacities, and instrumentation

Security measureTriple safety mechanisms are employed for excessive overheating.

Request technical documents for these models

Suitable for a wide range of applications, from testing temperature characteristics to heat treatment and drying. Programmed operation now allows storage of ten patterns, each with up to twenty steps. Provides a wide range of functions, including temperature ramp settings and up to 999 repeat cycles.

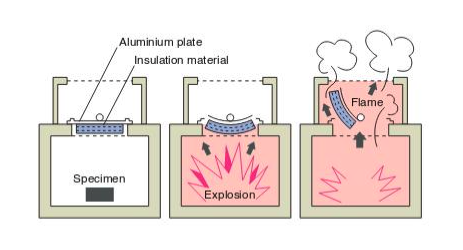

Thermal chamber with explosion-proof ventingThis industrial oven is suitable for drying and heat treatment of flammable synthetic resins or volatile solvents. Safety devices such as explosion-proof venting or door locking system (single-acting lever) allow safe operation.

Door equipped with single-acting leverLock, switch and alarm buzzer are fitted to deny operation when the door is open.

Request technical documents for these models

Areas of application

Areas of application

Electronic and electromechanical network stabilisers and conditioners:

- Production lines;

- Machine tools;

- Laboratories and test benches;

- Oil and gas installations.

MMM Group - Stoves and sterilizers

MMM is one of the leading suppliers of sterilization systems, stoves and incubators, with a mission to promote hygiene since 1954. It has a complete catalog of disinfection and sterilization products used by every healthcare sector, hospitals, scientific institutes, laboratories and pharmaceutical industries. The group has consolidated its position over time as a pioneer of quality and innovation in the German and world markets.

Production takes place in two plants: in Stadlern, Germany and in Brno, Czech Republic. The quality and precision of the products meet the most demanding standards and are perfectly suited to the rigor that characterizesmedical engineering. MMM is more than a manufacturer, providing a complete service from design, consultation, software programs, installation, logistics and process validation to the construction of extended projects for industry.

More than 1,000 employees work together to provide the best support to protect human health.

Products

LABORATORY STOVES

The MMM Group produces a wide range of cost-effective laboratory stoves.

The devices are available in "ECO line" and "EVO line" versions with slightly different instrumentation and panels and more advanced features.

ECO Line

EVO Line

The E-CELL is a line of economical drying ovens with a wide temperature range, naturally accurate and reliable. These ovens are suitable for simple drying and heating processes. The line features quiet operation and optimal airflow within the usable space.

Following a door opening, the stove ensures a rapid return to the set operating temperature.

E-CELL devices meet legislative technical conditions and regulations in CZ and EU.

- Inner chamber sizes: 22, 55, 111, 222, 404, 707 liters

- Operating temperatures: from 5°C above room temperature up to 250°C (extendable up to 300°C optional)

- Interior: stainless steel, matte No.1.4301 (AISI 304)

ECELL Laboratory Stove

Accurate and fast, V-CELL forced circulation stoves have high-end requirements.

The V-CELL line, thanks to its patented forced air circulation system, guarantees a uniform temperature profile for all drying and heating processes. Rapid heating and precision of all hardening processes characterize these units, which also ensure economical operation. These units are particularly suitable for materials with high humidity.

- Inner chamber sizes: 22, 55, 111, 222, 404, 707, 1212 liters

- Operating temperatures: from 10° C above room temperature up to 250° C (extendable up to 300° C optional)

- Interior: stainless steel, matte No.1.4301 (AISI 304)

V-CELL forced-ventilation stoves

Fast, economical and environmentally friendly vacuum stoves.

This line of stoves are designed for vacuum drying with the possibility of extrusion from inert gas.

They can be used for thermolabile materials and oxidation-sensitive substances oxidation (powder, granulates, ...) but also for extremely complex components. These units are ideal for constant mass sample drying used mainly in the plastics processing, pharmaceutical, chemical, electrical and other industries.

- Inner chamber sizes: 22, 55, 111 liters

- Operating temperatures: from 5°C above room temperature up to 200°C

- Interior: stainless steel, matte No. 1.4571(AISI 316Ti) pressure resistant

- Door: clear glass

- Inert gas connection with valve for fine adjustment

Vacuum stoves VV-CELL

LABORATORY INCUBATORS

High-techincubation systemswith heating, cooling and light control functions. These products are intended for use in research, development, production, commercial activities, or quality control.

All devices are available in "ECO line" and "EVO line" versions with slightly different instrumentation and panels and more advanced features.

ECO Line

EVO Line

Natural convection incubators.

Suitable for the safe treatment of microbiological cultures. The I-CELL line is extremely quiet provides a very smooth airflow within the chamber. These devices can be used primarily in biological and microbiological laboratories, quality testing in the pharmaceutical and cosmetic industries, and for experimentation in veterinary and food medicine.

- Inner chamber sizes: 22, 55, 111, 222, 404, 707, 1212 liters

- Operating temperatures: from 5° C above room temperature up to 99.9° C

- Interior: stainless steel, matte No.1.4301 (AISI 304)

I-CELL Incubator 22 liters

Forced ventilation incubator.

Suitable for safe incubation of microbiological cultures. The IV-CELL line (with a fan) ensures faster and more precise temperature distribution with minimal deviations. These units are especially suitable in biological and microbiological laboratories. They can also be used for quality testing in the pharmaceutical and cosmetic industries, for testing in veterinary medicine, and in the food industry.

- Inner chamber sizes: 22, 55, 111, 222, 404, 707, 1212 liters

- Operating temperatures: from 10° C above room temperature up to 99.9° C

- Interior: stainless steel, matte No.1.4301 (AISI 304)

IV-CELL ventilated incubator 404 liters

Incubator with precise chiller to simulate natural processes.

F-CELL units enable time- and space-accurate thermostatting of samples. The unique cooling system offers precise simulation of natural processes with low evaporation in the sample. Incubators can be used in the biotechnology, botanical, zoological and food, pharmaceutical, cosmetic and chemical industries.

All devices in this series have very low times to re-establish set conditions.

- Inner chamber sizes: 22, 55, 111, 222, 404, 707 and 1212 liters

- Operating temperatures: from 0° C up to 99.9° C (-20°C upon optional request)

- Refrigerant: R 134a CFC-free ( for - 20°C R449a CFC-free)

- Defrosting control: manual

- Interior: stainless steel, matte No.1.4301 (AISI 304)

F-CELL 55 Incubator

Cell growth incubator with protective atmosphere.

The CO2CELL series is suitable for research and growth of cells and other cultures. The operation of CO2CELL incubators is based on the gravitational flow of gas in the electrically heated chamber with high relative humidity. The gas concentration level can be selected. The unit is very quiet during operation.

As standard, a 'CO2 protective atmosphere is used. Depending on customer requirements, O2 or NO2 can be used. The CO2 concentration in the chamber is detected by means of an infrared sensor with an automatic calibration cycle.

- Internal chamber sizes: 50 and 190 liters

- Operating temperatures: from 5° C above to room temperature up to 60° C

- CO2 concentration: 0.1% to 20%.

- Interior: stainless steel, matte No.1.4301 (AISI 304) or DIN 1.4571 (AISI 316)

CO2-CELL Incubator

CLIMATIC CHAMBERS

Climate chambers in the ClimaCell product line provide all the conditions for accurate and reproducible simulation of different environmental conditions.

They are a key tool in stability testing phases of components, food containers or chemicals, or in germ, plant, tissue and insect studies.

These devices offer an attractive alternative to expensive test chambers and test rooms. A microprocessor-based system that controls humidification and dehumidification and a powerful lighting system ensure excellent homogeneous parameters for test and growth conditions.

All devices are available in "ECO line" and "EVO line" versions with slightly different instrumentation and panels and more advanced features.

ECO Line

EVO Line

- Internal chamber sizes: 111, 222, 404, 707 and 1212 liters

- Humidity-free operating temperatures: from 0° C up to 100° C

- Operating temperatures com humidity: from 10° C up to 90° C

- Refrigerant: R 134a CFC-free ( for - 20°C R449a CFC-free)

- Moisture generation liquid: distilled water

- Humidity range: 10% 98% RH

- Interior: stainless steel, matte No.1.4301 (AISI 304)

Climacell climatic chamber

HOT AIR STERILIZERS

The MMM Group offers a complete line for hot air sterilization. These devices can be used for perfect, fast and accurate sterilization, drying and heating in the health care industry.

The sterilization effect is achieved by the forced circulation of dry air at a specified temperature for a defined time.

Usually, temperatures of 160°- 180°C are ideal for sterilization processes with times ranging from 30 to 60 minutes.

Sterilizer in accordance with European regulations no. 93/42/EEC.

This instrument is suitable for medical and veterinary clinics, hospitals, pharmacies, medical and beauty centers, dentists etc.

Small stores can also take advantage of the 22 l countertop model without taking up large spaces. Three sterilization programs are already set.

All these models are controlled by a "Fuzzy logic" microprocessor for better accuracy assurance. In addition, a delayed start function is available.

- Inner chamber sizes: 22, 55, 111, 222, 404 liters

- Operating temperatures: from 10° C above to room temperature up to 250° C

- Interior: stainless steel, matte No.1.4301 (AISI 304)

Stericell Sterilizer

Areas of application

Areas of application

- health sector;

- hospitals;

- scientific institutes;

- labs

- pharmaceutical industries