SGM Lektra

Measurement and control in the process

The company

For 40 years in the field of industrial and process instrumentation

Since 1977, Sgm-Lektra has been producing instruments for measurement and control in industrial processes, the integrated water cycle and temperature monitoring in the food processing and milling industries. SGM-Lektra offers solutions for level, flow, chemical analysis, pressure and temperature measurement.

SGM Lektra Products

LEVEL measurement and control

LEVEL GAUGES - ULTRASONIC

It is a measuring principle that works without contact with the product to be measured.

The sensor sends out short ultrasonic pulses that are reflected from the product surface and again picked up by the sensor. From the exact measurement of the time between pulse emission and echo reception, the distance to the surface and consequently the level measurement is derived. An internal digital temperature sensor corrects the measurement according to the air temperature.

Our ultrasonic level transmitters are suitable for measurements on liquids and granulates for distances up to 10 meters.

Concentrated acids, toxic wastes, vapors, presence of agitators, and measurements in by-pass tubes are no obstacles to their application thanks to an advanced signal processing system and sophisticated analysis of the received echo.

Depending on the applications are available:

- IP68 transmitters, PTU series up to 12 m

- IP67 compact units with removable display METER series up to 10 m

- IP66 compact units with remote display for KTU series calibration up to 10 m

- associated units; VLW90M - VLW60T

Depending on the 2- or 4-wire technology, HART, MODBUS RTU or BLUETOOTH communication can be used. Softwares to be installed on a PC or Android App for communication and calibration of the units are available on request. ATEX versions are available for applications in hazardous locations.

Range 0.25 ÷ 6 m / 0.4 ÷ 10 m

IP67 protection

Suitable for measuring liquids and granulates

Com port. MODBUS

Power supply 24 Vdc; 12 Vdc

4 to 20 mA output (2-wire vers.);

4 ÷ 20 mA + 2 settable relays (4-wire vers.)

ATEX Certification

Remote control via Smartphone

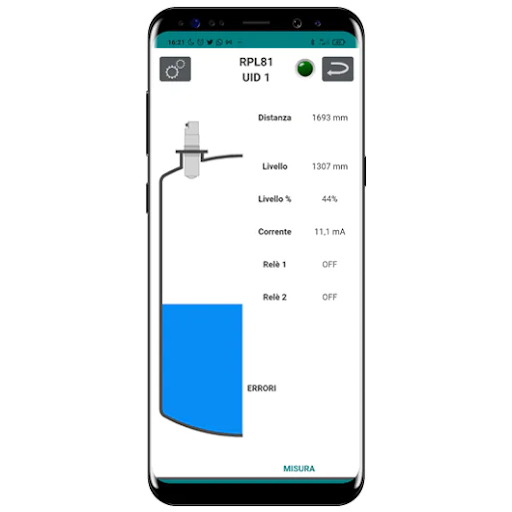

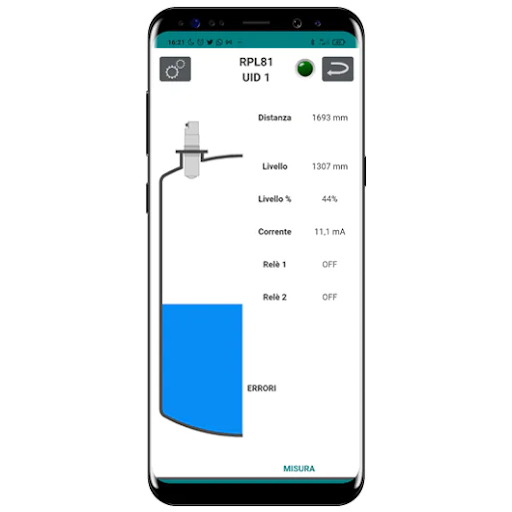

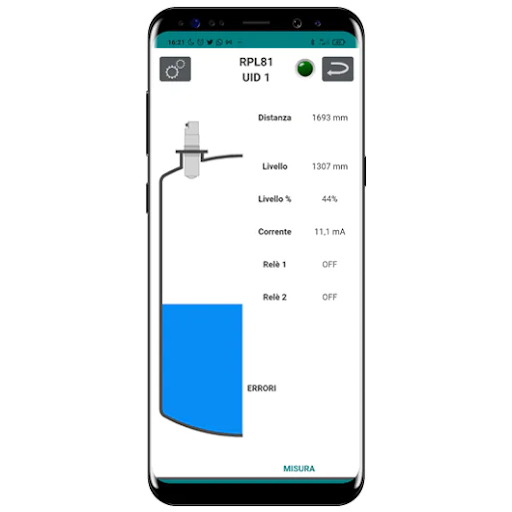

SGM BT Multisensor Application

SGM BT.

Useful for calibrating, programming and displaying SGM-Lektra* sensors. For PTU51/56, RPL75/81, Meter6/10m and RPmag level transmitters. Compatible with Android 5 or higher devices. Connection via Bluetooth.

The SGM BT App is compatible with smartphones and Android tablets of the most popular brands. With SGM BT it is possible to program, calibrate and configure SGM-LEKTRA measurement instrumentation equipped with Bluetooth connection.

The graphics of the measurements and programming menus, makes the App easy to navigate and intuitive to use for configuration and calibration of all instruments combined with it.

SGM BT allows remote viewing (max 10m in free air) of level, or flow rate, measurements in real time.

*The SGM LEKTRA instruments available with Bluetooth connectivity (optional) are:

- METER ultrasonic level transmitters, PUT51 and PTU56

- RPL75 and RPL81 80GHz Radar Level Transmitters

- RPmag, RSmag and RKmag electromagnetic flow meters

- FLOWMETER and FLOW51 ultrasonic flow meters

Ultrasonic level transmitter

Range 0.25 ÷ 6 m / 0.4 ÷ 10 m

IP67/68 protection

Suitable for measuring liquids and granulates

Com port. MODBUS

Power supply Vdc (12,24) and Vac (24, 115, 230)

Output 4 ÷ 20 mA + 2 settable relays

Features:

Compact ultrasonic unit for general applications in liquids and bulk solids. KTU5 has 3 programming modes:

"on board" button programming

programming with VL621, "remote display"

programming with s/w modbus rtu "sw 010F105A"

The KTU ultrasonic level transmitter is required for its compactness in installations where local display is not important. Very flexible in the choice of supply voltage; 12; 24 Vdc, 24 Vac, 115 Vac, 230 Vac. Two configurable relays allow realization of alarm thresholds and pump drive control. Complete self-diagnostics makes it suitable for unattended measurements. Another outstanding feature is the use of a single material of construction (PP), making it suitable for uses with strong presence of acid vapors.

Units for measuring levels, open channel flow rates, and pump control

VLW90M is a multifunctional unit, suitable for connection via MODBUS RTU of SGM LEKTRA ultrasonic level sensors PTU50/51/56, MTU5, KTU5 and METER for data acquisition and display with integrated management of: levels, flow rates, pumps. Integrated data logger with data storage on memory pen (USB).

Features:

- Level control, flow rates, pump automation

- 6 independent level measurements

- 2 flow measurements in open channels

- 2 measures of volume

- 1 differential level measurement pump control (lifting) up to 5 submersible pumps

- 2 analog outputs 4÷20mA

- 1 Modbus slave output

- 5 fully configurable relays

- 2 open collector digital outputs

- 2 analog inputs 4÷20mA

- 2 digital inputs (max. 24Vdc 10mA)

- Datalogger on USB Pen Drive

Modbus radar and ultrasonic level display and configuration unit

- 4.3" touch screen display

- Up to 3 simultaneous level measurements

- Graphic visualization of levels

- On-board relay status display indication

- METER transmitter, KTU, RPL81

Features:

Display and configuration unit for Modbus SGM-LEKTRA level transmitters via 4.3" color touch screen display. Connection of up to 3 transmitters fully programmable using a simple and intuitive menu. Level display expressed in metric units or in percent. Display indication of transmitter on-board relay status. Level measurements are displayed according to a user-selected configuration with manual or automatic scrolling of display pages.

Ultrasonic level transmitter

- Ultrasonic level transmitter

- Measuring range 0.05 to 1.5 meters

- Blocking distance 5 cm

- IP68 sensor protection

- PP sensor body

- Suitable for measuring liquids

- MODBUS RTU Communication Protocol

- Analog output 4 ÷ 20 mA

Features:

The application of non-intrusive measuring systems is still the preferred one today. For this reason, SGM-LEKTRA has developed the PTU50 ultrasonic level transmitter. Together with its compactness, the PTU50 unit offers unique ease of commissioning. Calibration and configuration of PTU50 level transmitters is possible, even remotely, by means of a MODBUS RTU connection together with the corresponding PC software, or via the VLW90M / VLW60T display and power supply units. The IP68 degree of protection allows application inside manholes below the floor level.

Ultrasonic level transmitter

- Ultrasonic level transmitter

- Measuring range 0.3 ÷ 6 meters

- Blocking distance 30 cm

- IP68 sensor protection

- Suitable for measuring liquids and granulates

- MODBUS RTU / BLUETOOTH Communication

- Analog output 4 ÷ 20 mA

- Remote control via Smartphone

Features:

The application of non-intrusive measuring systems is still the preferred one today. For this reason, SGM-LEKTRA has developed the PTU51 ultrasonic level transmitter. Together with its compactness, the PTU51 unit offers unique ease of commissioning. Calibration and configuration of PTU51 transmitters is possible, even remotely, by means of a MODBUS RTU connection together with the corresponding PC software, or via the VLW90M / VLW60T display and power supply units. The IP68 degree of protection allows application inside manholes below the floor level. The application for configuration and programming via Bluetooth, available on Google Play, is compatible with smartphone devices, from leading manufacturers, with ANDROID 4.2 and later operating system. it is possible to read the detected measurements and set the sensor configuration parameters. The smartphone terminal must be equipped with the BLUETOOTH device of class 1 and version 2.1. The maximum receiving/transmitting distance is 15m in free air.

Ultrasonic level transmitter

PTU56 Ultrasonic Level Transmitter

- Ultrasonic level transmitter

- Measuring range 0.5 to 12 meters

- Blocking distance 50 cm

- IP68 sensor protection

- Suitable for measuring liquids and granulates

- MODBUS RTU / BLUETOOTH Communication

- Analog output 4 ÷ 20 mA

- Remote control via Smartphone

Features:

The application of non-intrusive measuring systems is still the preferred one today. For this reason, SGM-LEKTRA has developed the PTU56 ultrasonic level transmitter. Together with its compactness, the PTU56 unit offers unique ease of commissioning. Calibration and configuration of PTU56 transmitters is possible, even remotely, by means of a MODBUS RTU connection together with the corresponding PC software, or via the VLW90M / VLW60T display and power supply units. The IP68 degree of protection allows application inside manholes below the floor level. The application for configuration and programming via Bluetooth, available on Google Play, is compatible with smartphone devices, from leading manufacturers, with ANDROID 4.2 and later operating system. it is possible to read the detected measurements and set the sensor configuration parameters. The smartphone terminal must be equipped with the BLUETOOTH device of class 1 and version 2.1. The maximum receiving/transmitting distance is 15m in free air.

SGM BT Multisensor Application

SGM BT.

Useful for calibrating, programming and displaying SGM-Lektra* sensors. For PTU51/56, RPL75/81, Meter6/10m and RPmag level transmitters. Compatible with Android 5 or higher devices. Connection via Bluetooth.

The SGM BT App is compatible with smartphones and Android tablets of the most popular brands. With SGM BT it is possible to program, calibrate and configure SGM-LEKTRA measurement instrumentation equipped with Bluetooth connection.

The graphics of the measurements and programming menus, makes the App easy to navigate and intuitive to use for configuration and calibration of all instruments combined with it.

SGM BT allows remote viewing (max 10m in free air) of level, or flow rate, measurements in real time.

*The SGM LEKTRA instruments available with Bluetooth connectivity (optional) are:

- METER ultrasonic level transmitters, PUT51 and PTU56

- RPL75 and RPL81 80GHz Radar Level Transmitters

- RPmag, RSmag and RKmag electromagnetic flow meters

- FLOWMETER and FLOW51 ultrasonic flow meters

🇮 LEVEL GAUGES - RADAR

SOLE ITALIAN MANUFACTURER

The instrument's antenna sends very narrow electromagnetic pulses in the 26 GHz baseband (K-band).

These pulses are radiated by the antenna and then reflected off the surface of the product to be measured and picked up again by the same antenna. A time-extension method allows the evaluation of the time of flight, which by its nature is particularly short, so that the distance and thus the level of the product to be measured can be accurately calculated. Dusts, vapors, high temperatures and pressures are well tolerated, allowing the units to be used in heavy-duty applications. An advanced echo curve processing system and the ability to map false echoes enable optimized measurements even under critical conditions. Thanks to the two-wire (2-wire) technique and HART communication, it is particularly easy to connect and operate the units.

The instrument antenna sends electromagnetic chirp pulses in the W-band.

These waves are radiated by the antenna and then reflected off the surface of the product to be measured and picked up again by the same antenna. The FMCW method combined with furier transforms makes it possible to accurately calculate the distance and thus the level of the product to be measured. The W-band, with a frequency sweep of electromagnetic waves in the region of 80GHz, allows the surface detection of products whose dielectric constant is low.

Radar pulse level transmitter

RPL55 K-band radar pulse level transmitter

- Radar level transmitter

- Radar level measurement for liquids, pastes and slurries

- Measuring range 10 m

- Max process pressures up to 3 bar

- 2 /4 wire technology

- Radar pulses at 26 GHz (K-band)

- ATEX Certification

Features:

RPL55 is a radar sensor for continuous measurement on liquids, even chemically aggressive ones, under not particularly severe process conditions. It is suitable for level measurement in tanks with threaded connections 1½"G. The small antenna allows mounting in stilling wells or small tanks, and the availability of different sizes of the antenna extension also allows installation in the presence of insulation or other thicknesses to be overcome.

Radar pulse level transmitter

RPL58 K-band radar pulse level transmitter

- Radar level transmitter

- Continuous non-contact level measurement for bulk solids and powders

- Measuring range 70 m

- Radar pulses at 26 GHz (K-band)

- Alphanumeric display of level measurement and echo signal curve

- ATEX Certification

Features:

RPL58 is a radar sensor that can be used for continuous measurement of bulk solids. It is suitable for use in silos and storage facilities in sheds large size, even under severe process conditions. Suitable for level measurement in tanks with threaded connections 1½"G no flanged.The different antenna models and the wide temperature and pressure range make the RPL58 unit the optimal solution for almost all types of applications.

Radar pulse level transmitter

RPL59 radar level transmitter

- Radar level transmitter

- Continuous non-contact level measurement for bulk solids and powders.

- Measuring range 35 m.

- Radar pulses at 26 GHz (K band).

- Alphanumeric display of level measurement and echo signal curve.

- ATEX Certification

Features:

RPL59 is a radar sensor that can be used for continuous measurement of bulk solids. Suitable for use in silos, even under severe process conditions. Suitable for level measurement in tanks with 1½"G threaded or flanged connections. Different antenna designs and a wide temperature and pressure range make the RPL59 unit the optimal solution for almost any type of application.

Radar pulse level transmitter

RPL75 Level Transmitter

- Continuous non-contact level measurement for liquids and solids

- For liquids (max 20m) and solids (max 10m)

- 80GHz Radar Pulses

- Visualization and configuration on removable display module

- 4÷20mA output; 2 configurable relays

- Remote control via Smartphone

Features:

Compact unit with removable programming and display display, for microwave level measurements (W band) on liquids. RPL75 is available in 4-wire version, with 2 relays programmable to different trip thresholds and Modbus RTU serial communication. Threaded 2 "G process connection made of PP (moplen) for compatibility with chemically aggressive environments. Measuring range is 0.5 to 20 meters (on liquids) and is guaranteed only in the case of conductive liquids. The polycarbonate housing is equipped with a transparent cover to allow viewing of the measured quantity via the VL601 display.

Radar Level Transmitter

- Radar level transmitter

- Continuous non-contact level measurement for liquids and solids

- For liquids (max 20m) and solids (max 10m)

- 80GHz Radar Pulses

- IP67/IP68 (Sensor) - IP68 optional.

- 4÷20mA output; 2 configurable relays

- Remote control via Smartphone

Features:

Compact IP67/IP68 RADAR unit for non-contact level and distance measurements in liquid applications. The RPL81 radar level transmitter, with microwave (electromagnetic) technology by its nature is insensitive to changes in temperature, pressure and relative humidity, achieving excellent measurement stability and accuracy. RPL81 has 4 programming modes: "on board" buttons (IP67 only); VL620/1 module, "remote display for calibration" ;s/w modbus rtu; Bluetooth + SGM Level APP. 4-20mA outputs and Modbus port ensure continuous transfer of measurement to analog and digital acquisition systems. Two configurable relays allow implementation of local alarm thresholds and pump control/drive. One relay of your choice can be programmed as an operation alarm as a complete self-diagnostic checks for proper operation and makes RPL81 suitable for unattended measurements. Another outstanding feature is the use of a single homogeneous material of construction (PP) which makes it suitable for uses with the presence of chemical agressors (acid vapors and others), and thus in storage tanks. RPL81 due to its characteristics is particularly suitable for measurements in water lifting and treatment plants as well as in environmental monitoring of river and lake levels.

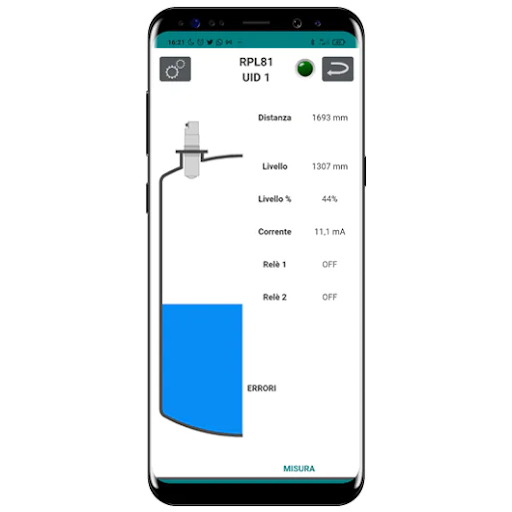

SGM BT Multisensor Application

SGM BT.

Useful for calibrating, programming and displaying SGM-Lektra* sensors. For PTU51/56, RPL75/81, Meter6/10m and RPmag level transmitters. Compatible with Android 5 or higher devices. Connection via Bluetooth.

The SGM BT App is compatible with smartphones and Android tablets of the most popular brands. With SGM BT it is possible to program, calibrate and configure SGM-LEKTRA measurement instrumentation equipped with Bluetooth connection.

The graphics of the measurements and programming menus, makes the App easy to navigate and intuitive to use for configuration and calibration of all instruments combined with it.

SGM BT allows remote viewing (max 10m in free air) of level, or flow rate, measurements in real time.

*The SGM LEKTRA instruments available with Bluetooth connectivity (optional) are:

- METER ultrasonic level transmitters, PUT51 and PTU56

- RPL75 and RPL81 80GHz Radar Level Transmitters

- RPmag, RSmag and RKmag electromagnetic flow meters

- FLOWMETER and FLOW51 ultrasonic flow meters

LEVEL METERS - CAPACITIVE

The capacitive principle for continuous level measurement is one of the most widely used in industry. Because of its adaptability, it can be applied for measurements on liquids, granulated solids, and powders. Operation is based on sensing the capacitance of the insulator interposed between the electrode and the material to be measured. The system can be compact (electrode and insert) in a single unit or separate with the insert remotely attached for reasons of high product temperature, high plant vibration, or practicality of use. The type of electrode chosen determines the unit model (CLT4, CLT8,...).

A capacitive electronic insert mounted inside a protective case determines the type of probe operation, namely:

- level transmitter, 4 to 20 mA (TC22 to 25)

- level transmitter, 4 to 20 mA + limit relay (TC26 to 29)

- level transmitter, 4 to 20 mA 2 wires (TC30)

The fully digital operation allows calibration by means of two pushbuttons or through a PC-installable s/w.

Guided Wave Radar Level Transmitter

RWL51 Guided Wave Radar Level Transmitter

- Radar level transmitter

- Continuous contact level measurement for liquids and solids

- Max rod length 3 m ; rope 30 m; semi-flexible tube 30 m

- TDR microwave pulses

- Alphanumeric display of level measurement and echo signal curve

Features:

A short electromagnetic pulse propagates along the rope and is reflected back once it reaches the end of the rope. If the rope is immersed in the product to be measured, an echo is generated in the area of insertion into the product by discontinuity that returns toward the probe itself and is detected as the surface of the product. A time elongation method allows the evaluation of the time of flight, which by its nature is particularly short, so that the distance and thus the level of the product to be measured can be accurately calculated. Particularly suitable for powders, granulates and lumped materials such as: plastic chips in high and narrow silos, in the food industry since new calibrations are not needed by changing the type of product, with building materials such as sands, gravels, etc... Calibrations are possible even in the absence of product. The instrument inputs high-frequency pulses through a probe. The pulses are reflected from the product surface, detected by the microprocessor electronic unit and converted into level measurement. The measurement technique, combined with the EchoDiscovery management system, allows RWL units to be used even under particularly harsh process conditions. The versatility of RWL transmitters allows their application in a variety of process types with the most severe conditions such as: high temperature, high pressure, low dielectric constant, etc. with materials such as cement, sands and others.

Capacitive level transmitter

CLT4 Capacitive probe for level measurement

- Contact level measurement

- Threaded, flanged and sanitary connections

- Suitable for measuring liquids and powders

- Protection IP66 to 67

- PTFE or PVC coatings

Features:

Capacitive rod level probe for general purpose or chemical/pharmaceutical use, suitable for level measurement of conductive liquids, nonconductive liquids and granulates. Installation at the top of metal tanks.

Capacitive rope probes for level measurement

CLT7 Capacitive rope probes for level measurement

- Capacitive level transmitter

- Contact level measurement for mounting from above

- PE coated rope

- For measurement of powders and granulates

- Protection IP66 to 67

- Max. length 30 m

Features:

Capacitive rope unit for continuous level measurement. For general use, suitable for level measurement in granulates and powders. Installation in the upper part of silos.

Capacitive rope probe for level measurement

CLT8 Capacitive rope probe for level measurement

- Capacitive level transmitter

- Contact level measurement for mounting from above

- Threaded, flanged and sanitary connections

- Suitable for measuring liquids

- Protection IP66 to 67

- PTFE or PVC coatings

Features:

Capacitive rope unit for level measurement, suitable for liquids. Mounting on top of metal tanks.

LEVEL GAUGES - HYDROSTATIC SWING

It is a highly reliable level measurement for liquids. Basically, the sensor measures the pressure of the liquid column above the measuring point.

This is a measure of relative pressure, converted to meters of liquid column and consequently to a level.

The level thus measured is transmitted with 2-wire 4 ÷ 20 mA technique.

They find application in the level measure of:

- tanks

- tanks and wells

- manholes for water lifting

- measurement of groundwater level

Installation is always from above. Sensor suspension, depending on the model, can be with tubes (rigid extension) or extension cable (flexible extension).

Hydrostatic swing level transmitter

- Hydrostatic swing level transmitter

- Accuracy ±0.5%

- Range from 1 ÷ 200 m H2O

- Submerged probe protection (wet part): IP68

- Power supply 10÷36Vdc (2-wire)

Features:

Suitable for continuous level measurement on liquids. Typical application areas are drinking water plants and artesian wells. The various possible confiìgurations make the KPL level transmitter suitable in most industries (petroleum, chemical, energy, metallurgical, pharmaceutical and food) and under various operating conditions. These features make it the ideal instrument in process automation for hydrostatic swing level measurement.

Hydrostatic swing level transmitter for wastewater

- Hydrostatic swing level transmitter

- Specific for wastewater

- Accuracy ±0.5%

- Range from 1 ÷ 200 m H2O

- Submerged probe protection (wet part): IP68

- Power supply 12÷30Vdc (2-wire)

Features:

KWL is a highly reliable level gauge for liquids, specifically in wastewater treatment. Hydrostatic swing level measurement exploits the direct relationship between the liquid level height and the pressure exerted on the sensor measuring diaphragm. The measured level/pressure change is transduced and transmitted via 4 ÷ 20 mA.

LEVEL CONTROLLERS - CAPACITIVE

The capacitive on-off principle is a well-established and widely used system for level control. The instrument consists of an electrode, suitable for the application, and an electronic insert mounted inside a protective case. Available inserts suit a wide variety of applications; on-off transmitters , alarms, pump control, even with Atex certificates for applications in hazardous areas. Process connections are of various types; threaded, flanged, sanitary. CLS9 and CLS5 probes can be installed on plastic or fiberglass tanks.

Capacitive level switch

CLS2 Capacitive level switch

- Contact level control

- Suitable for controlling liquids, powders and granulates

- Protection IP66 to 67

- ATEX Certified

- PTFE or PVC insulation

- Unit

Features:

Standard capacitive units with rod or rope extensions for general industrial use, suitable for ON-OFF level control in granulates, powders and liquids, protection IP66 ÷ 67.

Capacitive level switch

CLS4 Capacitive level switch

- Capacitive level switch

- Contact level control

- Suitable for controlling liquids, powders and granulates

- Protection IP66 to 67

- ATEX Certified

- PTFE or PVC insulation

Capacitive level switch

CLS5 Capacitive level switch

- Capacitive level switch

- Contact level control for mounting from above

- PP sensor element

- Suitable for the control of granulates and powders

- IP67 protection

- PEHD cable

- Maximum length 6 meters

Features:

CLS5 is a capacitive level control using state-of-the-art technology. CLS5 has a heat-sealed PP sensor that enables its use in a wide range of applications for level control of granulates or powders such as: cement, flour, animal feed, etc.. CLS5 is easily configured via the VL601 module. Maximum tensile load 3000 N.

Capacitive level switch

- Compact capacitive level switch

- Suitable for liquids, bulk solids and powders

- Poor adhesion of the product on the sensor surface

- Differentiation between foam and liquid

- Sensor status indication via multicolor LED

- Compact housing made of AISI316L

- PEEK-coated active zone

- IP67 protection (IP69K on request)

- Two separately configurable alarms

Features:

Suitable for the control of granulated solids or powders, conductive and nonconductive liquids, even with the presence of foam. CLS6 is designed for universal use in tanks, pipes, silos, hoppers and anything else that requires product presence/absence control. The mass reference built into the sensor also makes CLS6 suitable for application in tanks, pipes, etc. made of plastic materials. Calibration/configuration can be done, without the need for optional accessories, via an on-board button that can be activated with any metal object such as, for example, the tip of a screwdriver. The multicolor LED indicates different switching conditions simplifying process condition checks.

Capacitive level switch

CLS7 Capacitive level switch

- Capacitive level switch

- Contact level control for mounting from above

- Carbon steel/PE rope

- Suitable for the control of granulates and powders

- Protection IP66 to 67

- Max. length 30 m

- ATEX Certified

Features:

CLS7 is a rope-operated capacitive level control for heavy-duty applications, suitable for granulates and powders, protection IP66 ÷ 67, installation at the top of metal tanks.

Capacitive level switch

- Capacitive level switch

- Contact level control for plastic tanks

- Protection IP66 to 67

- Threaded or flanged side mounting

- PP / PVC Wetted Part

- Insertion 103/150 mm

Features:

Capacitive unit suitable for applications in plastic or fiberglass tanks for on-off control of acids or other chemically aggressive products. Installation in the side of tanks.

LEVEL CONTROLS - A VIBRATION Tuning fork.

This principle is particularly suitable for use on powders and granulates when changes in electrical capacitance or electrostatic charges make other principles ineffective. The operating principle is based on the vibration of two prongs, generated by the electronic insert, which is absorbed by the product when it comes into contact with the vibrating prongs. The electronic insert is removable and can be powered with any voltage. Calibration is fully digital, is done by means of two buttons and allows selection of the alarm type (max ÷ min), sensitivity (low ÷ high) and delay time (1s ÷ 4s). It is also available in an Atex version

Hydrostatic swing level transmitter

- Tuning fork level switch Tuning fork level switch

- Suitable for the control of granulates and powders

- G1"½ threaded connections

- SPDT Relay Output

- IP66 protection

- Universal AC/DC power supply

- ATEX certified

Features:

RSL200 enables level threshold control of powder or granule products by means of two vibrating prongs. Typical applications are overflow protection or product deficiency control (flour, cereal, milk powder, sand, cement, plastic or organic granules, expanded polystyrene, etc.).

Tuning fork level switch for liquids

- Tuning fork level switch

- Suitable for liquid control

- Material: AISI316

- Connections: G 1"; G 3/4"; G 1/2" DIN 2999

- Protection: IP66

- Outputs: NPN/PNP contact, SPST relay NO

Features:

Suitable for liquid control

Material: AISI316

Connections: G 1"; G 3/4"; G 1/2" DIN 2999

IP66 protection

Outputs: NPN/PNP contact, SPST relay NO

Suitable for controlling liquids such as oils, water, transparent paints and inks, sauces, milk, liquids containing carbon dioxide, foaming oils.

RSL100 is designed for universal use in tanks and pipelines.

FLOW METERS

FLOW METERS - ELECTROMAGNETIC

SGM LEKTRA has long dedicated activities in the field of flow measurement. With reference to magnetic induction flowmeters, the only requirement is that the liquid to be measured must have a minimum electrical conductivity.Magnetic induction flowmeters can be used, in all industries for measuring the flow rate of liquids in pipes from DN10 up to DN2000.

Depending on the type of application SGM LEKTRA has made 3 different product lines:

- RPmag; RKmag; RPmagM; RLmag: industrial process and water treatment

- RSmag: food and pharmaceutical sector

- RBmag : "stand alone" applications

All units offer advantages such as:

Bidirectional measurement - Extreme reliability - Excellent accuracy - No moving parts - No pressure drop - Measurement independent of liquid pressure, temperature, density and viscosity.

With this extremely reliable measurement technique, standard measurement accuracies of 0.5 percent over the measured value are achieved with the possibility of pushing the accuracy to 0.2 percent. Calibration of units is performed individually on internationally certified bench in compliance with European standards.

The relevant calibration certificate, an integral part of the delivery of these instruments, has international validity.

Calibration (wet) is performed on a system with accuracy better than 99.97%. The accuracy of the calibration system is certified and checked by the N.I.M. (National lnstitute of Metrology) metrology bureau. The N.I.M. institute, a third-party entity, is internationally recognized by the B.I.P.M. (Bureau International des Poids et Mesures), the calibration facility also complies with NTC ISO IEC 17025 requirements and calibration procedures in compliance with European EN-45001 standards.

INDUSTRIAL SECTOR/WATER TREATMENT

The RPmag and RKmag product line is suitable for the many applications in the "industrial process" field. Tantalum, hastelloy c, platinum, and titanium electrodes are available in addition to various coating materials. A wide range of materials allows applications with chemically aggressive liquids and suspended solids. A salient feature of the soft rubber coating is that it resists abrasion from water with suspended solids.

Electromagnetic flow meter with datalogger and Bluetooth

- Electromagnetic flow meter

- Flow measurement for conductive and chemically aggressive liquids

- Dn from 10 to 2000 mm

- Measurement accuracy: ± 0.2% ; ± 0.5%

- Neoprene / PTFE coatings

- Power supply 85÷265 Vac; 12Vdc ; 24 Vdc/Vac

- Datalogger on USB pendrive

- Removable O-LED display module

- Remote control via Smartphone

Features:

The RPmag product line is suitable for the many applications in the "industrial process" field. In addition to various coating materials, hastelloy c, tantalum and titanium electrodes are available. The converter is available with popular communication interfaces such as Modbus, Hart and via an Android smartphone application via Bluetooth. RPmag has an on-board data logger for recording measurements over time. The measured quantities are stored in a TXT file compatible with Excel or other equivalent software. The data logger physically consists of a USB pen drive. The USB port on the pen drive is located behind the removable O-LED display VL701.

Electromagnetic for zero-diameter installation

RKMAG Electromagnetic for zero-diameter installation

- Electromagnetic flow meter zero upstream/downstream distances

- Specific for "0-diameter" installations near bends, fittings etc....

- Dn 50 to 300 mm

- Accuracy of measurement: ± 0.5%

- Power supply 85÷265 Vac; 12Vdc ; 24 Vdc/Vac

- Remote control via Smartphone

Features:

SGM LEKTRA introduces the new range of RKmag electromagnetic flow meters, which, due to their special internal geometry, are less affected by the proximity of disturbing elements such as fittings, bends etc. and can therefore be installed at zero upstream/downstream distances. The electronic converter, with large and bright removable O-LED display, provides a data logger on a USB pen-drive. Transmission of flow measurement is possible via analog, pulse and MODBUS RTU outputs. Any alarm signaling occurs by means of No. 2 programmable relays. The RKmag meter is suitable for use with a wide range of conductive liquids, even chemically aggressive ones, thanks to the possibility of selecting the most suitable electrode material for the application.

MID-certified electromagnetic flow meter

RPMAGM MID Certified Electromagnetic Flow Meter

- MID-certified electromagnetic flow meter

- Dn from 10 to 250

- Accuracy of measurement: class II

- Neoprene / PTFE coatings

- Power supply 85÷265 Vac; 12Vdc ; 24 Vdc/Vac

- Removable O-LED display module

Features:

The RPmagM product line is suitable for multiple applications in the "industrial process" field. MID certification according to Directive 2014/32/EU, and conforming to OIML49 R - EN14154 - ISO4064 standards, makes RPmagM suitable for all fiscal uses. In addition to various coating materials, hastelloy c, tantalum and titanium electrodes are available. The converter is available with popular communication interfaces such as Modbus.

Electromagnetic flow meter for low flow rates

RLMAG Electromagnetic flow meter for low flow rates

- Electromagnetic flow meter for low flow rates

- Accuracy < (±0.8% of measured value + 0.5% of full scale)

- Gauge body totally made of AISI 316L

- PEEK inner coating

- Fully configurable measurement, monitoring and dosing functions

- Two-way measurement

- Max. pressure 16bar; max. temperature 70°C

- Threaded process connections

- Color display with 90° display rotation

Features:

Meter suitable for measuring flow rate values from a minimum of 0.04l/m (DN5) to a maximum of 100l/m (DN15). The all-AISI 316L body makes o instrument also suitable for chemical/food applications. The small size and multiple varieties of threaded connections make it easy and quick to install mechanically. Rotation of the TFT display allows horizontal or vertical mounting orientation.

FOOD/PHARMACEUTICAL SECTOR

Electromagnetic flow meter with datalogger and Bluetooth

RSMAG Electromagnetic flow meter with datalogger and Bluetooth

- Electromagnetic flow meter

- Dn 25 to 200 mm

- Connections DIN 11851 and CLAMP DIN 32676

- Measurement accuracy: ± 0.2% ; ± 0.5%

- PFA coatings

- Power supply 85÷265 Vac; 12Vdc ; 24 Vdc/Vac

- Datalogger on USB pendrive

- Removable O-LED display module

- Remote control via Smartphone

Features:

The RSmag line is aimed at applications in the food and pharmaceutical industries. DIN 11851 or CLAMP DIN 32676 type connections make it possible for use in industries such as dairy, breweries and others. The construction is completely made of stainless steel, and PFA coatings are available for the pharmaceutical sector. The converter is available with popular communication interfaces such as Modbus, Hart and via an Android smartphone application via Bluetooth. RSmag has an on-board data logger for recording measurements over time. The measured quantities are stored in a TXT file compatible with Excel or other equivalent software. The data logger physically consists of a USB pen drive. The USB port on the pen drive is located behind the removable O-LED display VL701.

"STAND ALONE" APPLICATIONS

Battery-operated electromagnetic flow meter

RBMAG Battery-operated electromagnetic flow meter

- Battery-operated electromagnetic flow meter

- Measuring range DN10 to 800

- Accuracy of measurement: ± 0.5%

- GPRS data transmission

- Battery-powered, max. range 6 years

- Analog, pulse and MODBUS RTU outputs.

- Parameter programming via remote module

- IP68 protection

Features:

Battery-powered RBmag meters do not require an external power supply, so they are a viable alternative to conventional mechanical measuring systems and in isolated applications without a power supply.

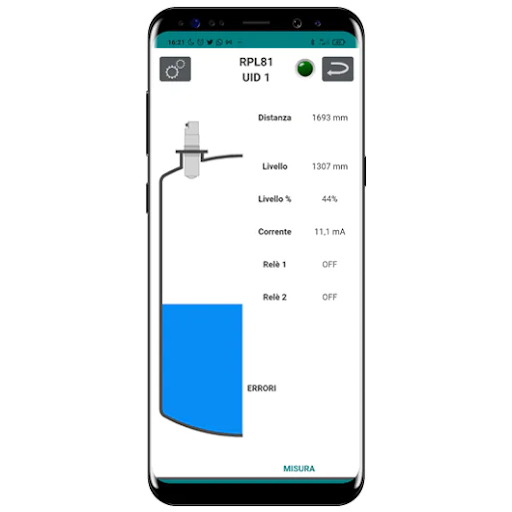

SGM BT Multisensor Application

SGM BT.

Useful for calibrating, programming and displaying SGM-Lektra* sensors. For PTU51/56, RPL75/81, Meter6/10m and RPmag level transmitters. Compatible with Android 5 or higher devices. Connection via Bluetooth.

The SGM BT App is compatible with smartphones and Android tablets of the most popular brands. With SGM BT it is possible to program, calibrate and configure SGM-LEKTRA measurement instrumentation equipped with Bluetooth connection.

The graphics of the measurements and programming menus, makes the App easy to navigate and intuitive to use for configuration and calibration of all instruments combined with it.

SGM BT allows remote viewing (max 10m in free air) of level, or flow rate, measurements in real time.

*The SGM LEKTRA instruments available with Bluetooth connectivity (optional) are:

- METER ultrasonic level transmitters, PUT51 and PTU56

- RPL75 and RPL81 80GHz Radar Level Transmitters

- RPmag, RSmag and RKmag electromagnetic flow meters

- FLOWMETER and FLOW51 ultrasonic flow meters

FLOW METERS - ULTRASONIC, TRANSIT TIME

SGM-101F and SGM-101H meters operate on the principle of transit time difference of ultrasonic pulses.

The great advantage is in installation, as it is not necessary to cut the pipe. The sensors simply need to be banded on the outer surface of the pipe, reason why pressure and aggressiveness of the liquid to be measured are not a problem for the meter. The system measures bidirectionally and is suitable for clean or moderately dirty liquids.

Ultrasonic flow measurement transit time

- Transit time flow meter

- Suitable for conductive and non-conductive fluids

- Campi di misura da <0,2m3/h a >400000 m3/h

- Accuracy of measurement: ± 1%

- IP68 clamp-on sensors also for high temperature and insertion

- Pipe measurement range: DN20 TO DN4000

- Datalogger on SD card or via MODBUS

- Hour meters

Features:

SGM-101F transit time flow meters operate on the principle of transit time difference of ultrasonic pulses. The great advantage is in installation, as it is not necessary to cut the pipeline. The sensors simply have to be banded on the outer surface of the pipe, reason why pressure and aggressiveness of the liquid to be measured are not a problem. In addition, insertion transducers specifically for concrete pipes are also available. The system measures bidirectionally and is suitable for clean or moderately dirty liquids.

Ultrasonic flow measurement transit time

SGM-101H Ultrasonic flow rate measurement transit time

Portable system suitable for conductive and non-conductive fluids even with the presence of suspended material (<10g>

- Campi di misura da <0,02m3/h a >24000m3/h

- Accuracy of measurement: ± 1%

- Clamp-on sensors on metric ruler

- Measuring range DN25 to DN1200

- Datalogger on SD card Backlit LCD display

- Battery life: max 6h

- Analog output 4÷20mA

- MODBUS RTU digital communication

Features:

The SGM-101H flow measurement system consists of a digital converter and two ultrasonic transducers. The transit time of a luid, inside a cylindrical section pipe, is the operating principle on which the instrument is based to calculate the instantaneous flow rate value. SGM-101H has the 4÷20mA active output and MODBUS RTU communication port.

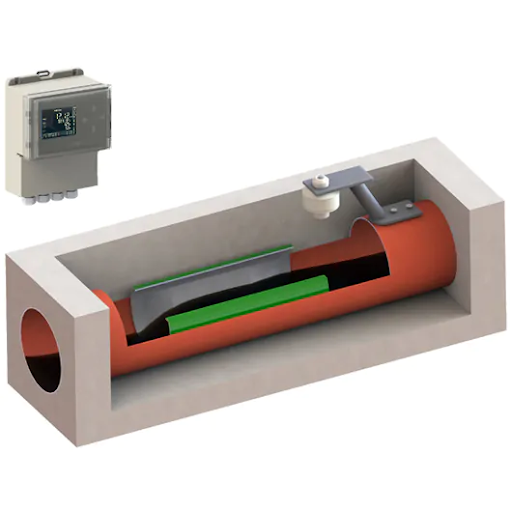

FLOW METERS - IN OPEN CHANNELS AND UNPRESSURIZED PIPES

Flow measurement in open channels using the hydraulic prominence method is accomplished by using, within the partially filled channel or pipe, a hydraulic shaper, a probe for level measurement (in this case ultrasonic, without contact with the liquid itself) and an associated control unit for converting the level into the corresponding instantaneous flow rate.

Measurement of flow rates in open channels or unpressurized pipes

Complete system for measurement in open channels CA400

Complete system for measuring flow rates in open channels

- 2 independent flow rate measurements

- Sensor measurement range 1.5; 6 meters

- IP68 sensor protection

- 2 analog outputs 4÷20mA

- 5 fully confi gurable relays

- 2 open collector digital outputs

- 2 analog inputs 4÷20mA

- 2 digital inputs (max. 24Vdc 10mA)

- Datalogger on USB Pen Drive

Features:

Flow measurement in open channels using the hydraulic prominence method is accomplished by using, within the partially filled channel or pipe, a hydraulic shaper (BS - Venturi channels / PB - Palmer Bowlus) or a weir, a probe for level measurement (in this case ultrasonic (PTU50; PTU51, without contact with the liquid itself) and an associated control unit (VLW90M). VLW90M is suitable for direct connection of 1 or 2 MODBUS ultrasonic sensors. Thanks to this feature, the CA400 system, can simultaneously perform two independent flow measurements with different ultrasonic sensors and hydraulic modelers for each type of channel. The presence of a "Data Logger" based on removable PenDrive, allows total traceability of flow measurements in open channels for which it is very easy to analyze the temporal profile of instantaneous flow rates.

HYDRAULIC PROMINENCE

Flow measurement in open channels using the hydraulic prominence method is accomplished by using, within the partially filled channel or pipe, a hydraulic shaper, a probe for level measurement (in this case ultrasonic, without contact with the liquid itself) and an associated control unit for converting the level into the corresponding instantaneous flow rate. Due to the ever-increasing integration of systems, a compact ultrasonic probe that incorporates both hydraulic level measurement and conversion into the corresponding instantaneous flow rate has been realized: flowmeter.

Measurement of flow rates in open channels or unpressurized pipes

Flowmeter

Complete system for measuring flow rates in open channels

- Compact flow meter

- Compact system suitable for installation upstream of hydraulic shapers (weirs, venturi, palmer bowlus)

- Solution with excellent price-performance ratio

- Measurement of instantaneous and total flow rate

- No. 2 freely programmable relays

- MODBUS Communication Protocol

Features:

Flowmeter is an ultrasonic open-channel flow transmitter, temperature compensated and suitable for connection with acquisition systems via MODBUS RTU. Flowmeter is a compact unit that in addition to an analog output includes 2 relays: RL1 for pulse output and RL2 for alarm threshold.

Compact flow meter

Flow51

- IP68 transmitter suitable for installation upstream of hydraulic shapers (weirs, venturi, palmer bowlus)

- Solution with excellent price-performance ratio

- Measurement of instantaneous and total flow rate

- Measuring range 0.3÷6m

- MODBUS Communication Protocol

Features:

FLOW51 is an IP68 compact ultrasonic flow transmitter, suitable for installations in sumps with flooding hazards. Its operating principle is based on the measurement of the hydraulic prominence (header); this measurement is then used to calculate the value of the instantaneous flow rate, depending on the hydraulic primary present in the channel.

FLOW51 can be confi gured, via MODBUS RTU or VLW601, for the main models of hydraulic primaries, such as: prefabricated SGM-LEKTRA VENTURI channels, PALMER-BOWLUS channels, all main weir models (rectangular with or without constriction, triangular and trapezoidal), PARSHALL channels, KHAFAGI VENTURI channels, etc.

In addition, flow measurement with non-standard hydraulic primaries can be configured via linearization table or customization of the outflow formula.

Compact flow meter

Modeling Hydraulic BS

- Venturi Channels - Hydraulic Modeling

- Installation in channels with rectangular cross section

- Flow rates 1 ÷ >7700 m3/h

- Low pressure drop

- Can be combined with all SGM LEKTRA systems for flow measurement on open channels

Features:

SGM-LEKTRA has developed in cooperation with the Institute of Hydraulics of the University of Pavia a family of venturi called "VENTURI BS." These measuring primaries are flat-bottomed venturi and suitable for installation in pre-existing rectangular channels.

They are suitable for use in irrigation systems, industrial wastewater treatment plants, sewage and turbid water in general; the continuous bottom plane without rises has a self-cleaning eff ect, does not promote debris deposition and can be easily inserted into existing rectangular channels. The submersed flow rate (ratio of upstream to downstream headwater) is well tolerated. The practical submergence limit for all models is about 90%.

In addition, flow measurement with non-standard hydraulic primaries can be configured via linearization table or customization of the outflow formula.

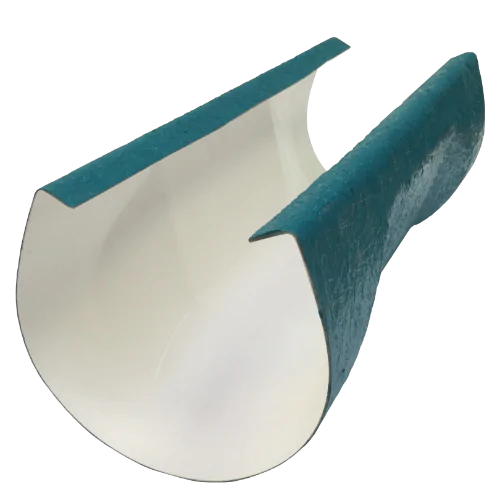

Compact flow meter

Palmer Bowlus - PB hydraulic shaper

- Palmer Bowlus - Hydraulic shaper

- Specific for flow measurement in outflow pipes or non-pressure pipes

- Direct installation in the pipe, or in manhole

- Flow rates from 0.45 to 1800m3/h

- Can be combined with all SGM LEKTRA systems for flow measurement on open channels

- Low cost

- Ideal for installations to measure flow values of a circular pipeline

Features:

SGM-LEKTRA has developed in cooperation with the Institute of Hydraulics of the University of Pavia a family of venturi called "VENTURI BS." These measuring primaries are flat-bottomed venturi and suitable for installation in pre-existing rectangular channels.

They are suitable for use in irrigation systems, industrial wastewater treatment plants, sewage and turbid water in general; the continuous bottom plane without rises has a self-cleaning eff ect, does not promote debris deposition and can be easily inserted into existing rectangular channels. The submersed flow rate (ratio of upstream to downstream headwater) is well tolerated. The practical submergence limit for all models is about 90%.

In addition, flow measurement with non-standard hydraulic primaries can be configured via linearization table or customization of the outflow formula.

SGM BT Multisensor Application

SGM BT.

Useful for calibrating, programming and displaying SGM-Lektra* sensors. For PTU51/56, RPL75/81, Meter6/10m and RPmag level transmitters. Compatible with Android 5 or higher devices. Connection via Bluetooth.

The SGM BT App is compatible with smartphones and Android tablets of the most popular brands. With SGM BT it is possible to program, calibrate and configure SGM-LEKTRA measurement instrumentation equipped with Bluetooth connection.

The graphics of the measurements and programming menus, makes the App easy to navigate and intuitive to use for configuration and calibration of all instruments combined with it.

SGM BT allows remote viewing (max 10m in free air) of level, or flow rate, measurements in real time.

*The SGM LEKTRA instruments available with Bluetooth connectivity (optional) are:

- METER ultrasonic level transmitters, PUT51 and PTU56

- RPL75 and RPL81 80GHz Radar Level Transmitters

- RPmag, RSmag and RKmag electromagnetic flow meters

- FLOWMETER and FLOW51 ultrasonic flow meters

PRESSURE MEASUREMENT

The SDT differential pressure transmitter is made with innovative silicon technology that distinguishes the product and makes it unique in reliability, accuracy and consistent performance over time. The sensor consists of a monolithic dual-chamber block with integrated overpressure protection system that protects the sensitive membranes; two separate pressure sensors, one differential and one absolute; and a temperature sensor.

The simultaneous action of these elements guarantees precision, linearity, stability and accuracy at the top of current market offerings. SPT's relative and absolute pressure measurement units are made using the same systems described for differential units and thus guarantee excellent stability and accuracy throughout the entire range of available pressures.

Main features:

- Sensors with high stability and accuracy up to ± 0.075% for SDT, SPT

- Differentials with static pressures of 160, 250, up to 400 bar

- Long-term stability < ± 0.1% over 3 years

- measuring range from 1 mbar to 600 bar

- rangeability 100 : 1

Completing the range are KPT, CPT series units aimed at aqueduct applications and for food plant installations.

KPT Suitable for measurements in liquid, gas and steam with male/female threaded connections, sanitary clamp (DIN32676) and vacuum (ISO 2861).

CPT Capacitive pressure transmitter suitable for waterworks and water treatment applications.

SPT With male/female threaded connections, specifically for applications on industrial processes with accuracy up to ±0.075% and for vacuum (ISO 2861).

SDT Differential pressure measurement with accuracy up to ± 0.075%, suitable for liquid, gas and steam measurements.

COMPATIBLE TRANSMITTERS

CPT compact transmitters

- Pressure transmitter

- Accuracy ± 0.2%

- Best value for money

- Threaded process connections

- Capacitive sensor with ceramic membrane

- High mechanical resistance to overpressure

Features:

CPT is a compact transmitter suitable for waterworks and water treatment applications.

Area velocity flow meter

- Pressure transmitter

- Accuracy ± 0.25%

- Best value for money

- Threaded, sanitary and vacuum connections

Features:

doneo to continuous level measurement on liquids. KPT is a pressure transmitter that can be used for measurement on liquids, gases, and vapors. The small-sized pressure transducer offers maximum reliability and operational safety. KPT is an economical solution for multiple applications in all areas of industrial process control.

PRESSURE MONITOR - SMART TRANSMITTERS

Smart pressure transmitter for use in industrial processes, flexible in its use due to high rangeability and various process attachment possibilities.

Smart SPT pressure transmitter

- Smart pressure transmitter

- Accuracy 0.075%

- Relative and absolute measurement

- Threaded, male or female, and vacuum process connection

- Hart Communication

- Backlit matrix display

- Parameter setting via display

- Self-diagnostics and fast response time

- ATEX

Features:

SPT is a pressure transmitter for use in industrial processes, flexible in its use due to its high rangeability and various process attachment possibilities. Thanks to its innovative technology, it is particularly stable over time and accurate in measurement. The internal temperature sensor corrects any deviations in the measurement caused by thermal changes in the process.

PRESSURE GAUGES - DIFFERENTIAL TRANSMITTERS

Differential pressure transmitter with top-of-the-line performance. Especially recommended for installations in processes where accuracy and stability are indispensable features.

SDT Differential Pressure Transmitters

- SDT differential pressure transmitter

- Accuracy 0.075%

- Range from 1 mbar to 20 bar

- Hart Communication

- Backlit matrix display

- Parameter setting via display

- Self-diagnostics and fast response time

- ATEX

Features:

SDT is a differential pressure transmitter with top-of-the-line performance. Especially recommended for installations in processes where accuracy and stability over time are must-have features.

Thanks to its technology, SDT can measure very low differential pressures as low as 1 mbar (10 mm H2O). SDT is fully programmable by means of the backlit matrix display and the two external watertight buttons.

This allows measurement parameters to be programmed or changed even in harsh environmental conditions, without having to access the instrument internally, thus maintaining the IP67 degree of protection.

Thickness measurements

ULTRASONIC THICKNESS GAUGES

- Compact digital thickness gauge

- Measuring ranges from 1.2mm to 225mm

- Suitable for steel, cast iron, PVC, glass etc.

- Measurement accuracy: ±0.5%

- Battery power supply

SGM-100T takes advantage of the transit time principle to achieve precision measurement. Due to its high emission and reception efficiency, SGM-100T can measure even on rough surfaces, such as cast iron, and can be used in almost all industries. SGM-100T can measure the thickness of many materials, ex: steel, cast iron, aluminum, red copper, brass, zinc, Glass, polyethylene, PVC, etc.

SGM-100T has the automatic shutdown system (after about 1 minute of non-use) to avoid unwanted power consumption, thus increasing battery life.

Areas of application

- Water treatment plants

- Basic Chemistry

- Industria alimentare

- Metallurgical and mining industry

- Construction industry and cement plants

- Grain milling and storage systems