IMADA

Torque and food tester

The company

Manufacturer of torque and food testers

IMADA CO.LTD is a Japanese company located in the heart of Japan in the city of Toyohashi that has made quality of life and development its vocation. Imada is considered a pioneer manufacturer of dynamometers in this field and a world expert in force measurement. IMADA has been present in Italy since 1955. In these years it has gained a solid reputation distributing high quality products to many companies. Production began back in 1947 with the first mechanical model with analogue dial used in the aircraft industry. During all these years IMADA has slowly built up its worldwide reputation thanks to the excellent products it has manufactured, the reliability it has shown and also for its excellent service. Today, IMADA instruments are used worldwide in a wide variety of applications.

IMADA products

Systems

FOOD PACKAGING

System for measuring food hardness

This simple test bench is ideal for measuring food hardness. It is suitable for performing compression tests on bread dough, meat, vegetables, etc. The lever position and compression distance are easily adjustable. The system allows repeatable and accurate measurements at a very attractive price. The unit includes a manual lever-operated stand model FCA-50N, a DS2-50N digital dynamometer and a choice of wedge or flat probe (choose the appropriate connection). The test bench is made entirely of stainless steel for easy cleaning. It is lightweight, easily transportable and is an ideal solution for all companies that need to testing the consistency of food products directly in the laboratory or on the production line.Maximum capacity: 500 N

Features:

- Manually operated test bench

- For tearing tests on cable lugs

- Horizontal stroke of 85mm

- Excellent in all endurance tests

- For tensile or compression testing

- Requires DS2 dynamometer

- Measures breakout force up to 50 kgf

- Sampling rate of 1000 Hz

- Easy-to-read LCD display

- Software included for data processing

- RS-232C output for connection to a PC

- BcD mitutoyo holder for statistical printer

System for measuring stiffness, viscosity, elasticity of foodstuffs

With the Food Texture Analyzer you can finally digitising food consistency and study the food characteristics such as stiffness, viscosity, elasticity, adhesiveness and much more, very simply and at a very attractive price. The instrument is a compact, lightweight and easily transportable structure analyser. Its ease of use and software-based data management make it an ideal solution for process control and indispensable in research and development, quality control and the laboratories of universities and research institutes. It meets a wide range of requirements in the field of textural analysis. It provides quantitative, repeatable and accurate data in a wide range of applications in the food, pharmaceutical and cosmetic industries.Maximum capacity: 50 N

Features:

- Easy to use and quick to clean

- Intuitive and clear touch screen

- 3 Procedures: Food, Standard, Program

- Library of ready-to-use tests

- Insertion of 1 own test on request

- Save max. 6 test conditions as favourites

- 3 different capacities: 5N, 50N, 100N

- Sampling rate of 1000 Hz

- Easy data management and analysis

- Saves data to pendrive or via software

- Software included for data processing

- Force/time and force/displacement graphs

- USB outputs, USB flash drive

- Made of stainless steel

- Wide range of testing devices

TORQUE TRANSDUCERS CLAMPING SYSTEMS

Digital benchtop torque transducers for food packaging

I digital benchtop torque transducers are excellent tools for the torque measurement. They are excellent for the food packaging. Easy to use, with high acquisition speed (2kHz), high sensitivity and excellent precision, they are available, with a choice of flow rates, in two versions: standard (mod. DTXS) or advanced (mod. DTXA). Easily transportable, they can be used both in the laboratory and on the production line. When installed on the MTS series stands, they can form an economical torque measuring system with motorised speed control, ideal for guaranteeing uniform results even with different operators and the possibility of carrying out durability tests that would be impossible to carry out manually. Displays both torque and angular displacement data when combined with motorised stands. Readings can be transferred from the internal memory to a USB Pendrive or saved directly to it.Maximum flow rate10 N/m

Sensitivity0.001 to 0.01 N/m

Sampling frequency2 KHz

Handheld digital torque transducers

I digital torque transducers are sophisticated microprocessor-based handheld instruments with an external measuring sensor, ideal for testing in the laboratory or on the production line, for the torque measurement of components, screw connectors, drive shaftsetc. The torque transducers in the series are available in an advanced version, model HTGA, or a standard version, model HTGS. Easy to use, with high acquisition speed (2kHz), high sensitivity and excellent accuracy, they are available with a choice of ranges. The advanced HTGA model also allows torsion angle measurement by equipping the instrument with a suitable angular transducer. They allow the maximum torque reached (peak value) to be recorded.Maximum flow rate2 to 50 N/m

Sensitivity0.001 to 0.01 N/m

Frequency sampling rate: 2 KHz

Request technical documents for these models

Handheld torque/angle measurement system

The portable torque/angle measurement system is space-saving and ideal for testing particular samples directly in their environment. The unit consists of a digital handheld torque transducer The instrument is equipped with a second channel dedicated to simultaneous angle measurement, an angle encoder located at the end of the torque handpiece, a fixture for gripping test specimens, a CB-728 cable and Force Recorder Professional software. The instrument's high sampling rate of 2000 Hz allows precise values to be captured and detailed graphs of torque versus angle to be drawn. The system can be configured in various ways to meet the different requirements of the samples being tested.Maximum flow rate2 to 10 N/m

Request technical documents for these models

TEST BENCHES

Manually operated crimp test system

Manually operated test bench for Tear tests on crimped, crimped, soldered or glued terminals. The system allows the peak breaking force of crimped and crimped cables to be measured by a simple lever movement. This tensile test is a fast and destructive method of assessing the mechanical properties of a termination. Tensile test results outside the permitted range are good indicators of problems in the production process. Tensile test results within the permissible range, on the other hand, ensure that adequate crimping forces have been applied during crimping. With this system it is possible to assessing the quality of the crimping process with extreme precision at a very advantageous cost.Maximum capacity: 500 N

Features:

- Manually operated test bench

- For tearing tests on cable lugs

- Horizontal stroke of 85mm

- Excellent in all endurance tests

- For tensile or compression testing

- Requires DS2 dynamometer

- Measures breakout force up to 50 kgf

- Sampling rate of 1000 Hz

- Easy-to-read LCD display

- Software included for data processing

- RS-232C output for connection to a PC

- BcD mitutoyo holder for statistical printer

Request technical documents for these models

Motorised automatic crimp test system

Digital tester designed for automate tear-off test processes of crimped, crimped, soldered or glued type terminals. Compliant with many standards, it can perform destructive tests (Break mode) as well as non-destructive tests (Keep mode) where it is necessary to pull up to a certain load or maintain a force for a defined period of time. The motor-controlled instrument has a horizontal drive with a maximum stroke of 50 mm and adjustable speed up to 300 mm/min.Maximum capacity: 1000 N

Speed10/25/50/100 mm/min or 25/50/100/300 mm/min (depending on model)

Features:

- Ideal for safely testing crimped cables

- Performs destructive and non-destructive testing

- Automate test processes

- Auto-reverse at the end of the test

- 2000 Hz sampling rate

- 26 presettable test configurations

- Measures breakout force up to 100 kgf

- OEL display visible even in the dark

- Intuitive and easy-to-use control panel

- Stores up to 1,500 data

- Software included for data processing

- USB, RS-232C, Digimatic and Analogue outputs

- Digital dial indicator -NG / OK / +NG

- Easy set up of samples

180° stripping force measuring system

Motorised test bench The horizontal stroke instrument is specially designed to perform reliable and repeatable 180° peeling tests with a digital output signal for data processing with a PC. The instrument provides extremely smooth and powerful operation over the entire speed range thanks to the combination of a worm gear driven by an innovative brushless motor. The instrument is ideal for measuring the force required to decouple specimens such as films and adhesive tapes at a very cost-effective price. The tester is CE marked and comes with specific software included. It can be used for 180° peeling tests: adhesive tapes, adhesive films, films.Maximum capacity5 to 50 N (depending on model)

Sensitivity: 0.001 to 0.01 N (depending on model)

Features:

- Low mechanical vibrations

- High sensitivity

- Sampling rate of 1000 Hz

- Measuring sensor and special software included

- Statistical data (maximum/minimum/average)

- Accurate Force/Time charts

- Easy connection to PC via USB port

- High performance and economic

- Intuitive and easy-to-use control panel

- Stores up to 1,000 data points

- Standard compliance (JIS C 0806-3 1999)

Request technical documents for these models

STATISTICS

Request technical documents for these models

Motorised horizontal stroke stand BASE

The horizontal travel stands consist of a sturdy painted die-cast aluminium base. Inside the base is a worm screw that moves on ball bearings. The rotation of the screw drives the mobile carriage with a constant movement which is controlled by a motor whose speed can be adjusted via the control panel. The dynamometer for measuring the force is fixed to the mobile crossbar and two manually adjustable mechanical limit switches limit the stroke. At the front are the operating controls and the emergency button. In the upper part of the table there is an anchor plate for fixing clamps or other support devices to secure the sample.Maximum loadup to 3000N

Force directionsTraction and Compression

Drive: Manual / Single-mode / Cyclic

Effective strokeup to 295mm

Request technical documents for these models

Horizontal motorised stand ADVANCED

The stand is an electric actuator with controlled and adjustable speed axial movement. On the front side are the emergency button, the LCD display, the control knob for digital setting of the various setting parameters shown on the display and the operating buttons for choosing the direction of movement (pulling/compressing). The series offers a more powerful operating range thanks to the possibility of choosing between the "Manualwhich allows the movement of the moving crossbar to be controlled via buttons on the panel, or the "Cyclical'.which allows continuous movement that can be programmed by number of cycles and time period. The speed is also programmable. In fact, it is possible to set 3 types of adjustable speed: start speed / measuring speed / return speed. Combining the stand with the advanced crane scales, connected with the special signal transmission cable, it is possible to work in "force control" mode, allowing the crane scale to automatically control the movement of the mobile crossbeam by means of the digital comparator (OK/NG), and to have the "overload stop" function active, which allows stopping the movement in the event of an overload. Thanks to the "Timer" and "Counter" functions, it is possible to carry out small fatigue tests with these stands.Maximum loadup to 500N

Deflection at maximum loadLess than 0.5mm

Force directionsTraction and Compression

DriveManual / Jog / Cyclic Digital setting of Speed / Counter / Time

Request technical documents for these models

Request technical documents for these models

Motorised vertical stroke stand BASE

The stand is an electric actuator with an axial movement at controlled and adjustable speed. On the front are the operating controls which allow speed adjustment (round knob), direction control, operating mode (single test, single cycle, repeated cycles) and also the setting of a fixed speed (set) by adjusting a trimpot screw potentiometer. The MX control panel does not have a display and adjustments cannot be controlled digitally. The MX stand offers two interesting functions when combined with the evolved dynamometers of the ZT series (or the previous Z series) connected with the appropriate signal transmission cable. The "overload stop regulates the stopping of movement in the event of an overload. The "force control allows the dynamometer to automatically control the movement of the moving crossbar via the digital dial gauge (OK/NG).Maximum loadup to 5000N

Force directionsTraction and Compression

DriveWith electric motor

Effective strokeup to 420mm

Request technical documents for these models

ADVANCED motorised vertical stroke stand

The motorised stands are vertical stroke sideshifters ideal for performing direct compression and tension tests at constant speed and with uniform axial movement. Versatile and high-performanceCompared with their predecessors in the MX series, the new MX2 series stands have been equipped with a large LCD display, a more solid mechanical structure and new features that make them a very attractive choice for all users. low-cost solution of the highest quality. The ADVANCED series offers a more powerful operating range thanks to the possibility of choosing between the "Manualwhich allows the movement of the moving crossbar to be controlled via buttons on the panel, or the "Cyclical'.which allows continuous movement that can be programmed by number of cycles and time period. Also the speed is programmable. It is possible to set 3 types of adjustable speed: start speed / measuring speed / return speed. Combining the stand with the advanced dynamometers, connected with the special signal transmission cable, it is possible to work in "force control" mode, allowing the dynamometer to automatically control the movement of the mobile crossbeam by means of the digital comparator (OK/NG), and to have the "overload stop" function active, which allows stopping the movement in case of overload. Thanks to the "Timer" and "Counter" functions, it is possible to carry out small fatigue tests with these stands.Maximum loadup to 2500N

Force directionsTraction and Compression

DriveManual / Jog / Cyclic - Digital setting of Speed / Counter / Time

Effective strokeup to 420mm

Request technical documents for these models

PROFESSIONAL motorised vertical stroke stand

Motorised stands are professional vertical travel sideshifters, ideal for perform direct tensile and compression tests constant speed and uniform axial movement. These brand-new motorised stands represent the top of the range of the motorised sideshifters. Built with a more solid mechanical structure that guarantees greater rigidity, they are also supplied as standard with all the functions that are optional on other stands.Maximum loadup to 1000N

Deflection at maximum loadLess than 0.25mm in the standard version and 0.6mm in the extended stroke version

Force directionsTraction and Compression

DriveManual / Jog / Cyclic Digital setting of Speed / Counter / Time Digital stroke setting Reversing movement at a selected change point

Request technical documents for these models

Request technical documents for these models

Stand with handwheel control

The stand is equipped with a handwheel control to provide a precise movementideal for applications that require relatively consistent speed and the maximum dynamometer control. The measuring instrument remains in position when the handwheel is released, allowing the user to easily change samples between tests. The crank control provides repeatable test results from sample to sample.Maximum load: 1000 N

Force directionsTraction and Compression

DriveWith handwheel control

Running: 60 mm

Request technical documents for these models

Stand with lever control

The stand is equipped with a lever control to perform compression and tension tests by a simple downward stroke of the lever. The test stand is designed to provide a simple move to change from compression mode to traction mode. Return springs reset the lever in compression mode and gravity does the work in traction mode. The stroke can be adjusted via a mechanical limit switch.Maximum load: 1000 N

Force directionsTraction and Compression

DriveWith lever control

Running: 60 mm

Request technical documents for these models

Stand with handwheel control HV

The stand is equipped with a handwheel control to provide a precise movementideal for applications requiring relatively consistent speed and maximum dynamometer control. The measuring instrument remains in position when the handwheel is released, allowing the user to easily change samples between tests. The hand crank control provides repeatable test results from sample to sample.Maximum loadup to 3000 N

Force directionsTraction and Compression

DriveWith lever control

Runningup to 379mm

Request technical documents for these models

Compact sideshifter with manual action

A indispensable accessory for testing membrane keyboards, small biomedical components, electronics and micromechanics in general.Maximum load: 50 N

Force directionsCompression

DriveWith knob control

Running: 70mm

Request technical documents for these models

Stand with lever control

The stand is equipped with a linkage control for performing compression testing by a simple downward stroke of the lever. The tester is ideal for testing small mechanical components and for testing the consistency of many products. food.Maximum load: 50 N Force directionsCompression

DriveWith lever control

Pre-settable stroke0-45mm

Maximum space50-80mm

Request technical documents for these models

Horizontal travel stand with handwheel control

The stand is equipped with a handwheel control to provide a precise horizontal movementideal for applications requiring relatively consistent speed and maximum dynamometer control. The measuring instrument remains in position when the handwheel is released, allowing the user to easily change samples between trials. The crank control provides repeatable test results from sample to sample.Maximum loadup to 3000N

Force directionsTraction and Compression

DriveWith handwheel control

Runningup to 320mm

Request technical documents for these models

Lever-operated stand for tear-off tests on cable lugs

The stand consists of a sturdy, heavy-duty base with painted aluminium panels and a rapid lever control. The dynamometer is fixed by screws on the mobile slide to apply uniaxial stress in traction or compression. The bench and dynamometer are equipped with metric threaded anchors for quick change of accessories. Load capacity up to 50 Kgf, excellent in all endurance tests. It is operated by means of a lateral lever with a linear movement of the mobile plate on which the dynamometer is fixed.Maximum loadup to 500N

Force directionsTraction and Compression

DriveWith lever control

Running: 85mm

Request technical documents for these models

DYNAMOMETERS

They are available in various versions for capacities from 2N to 1000N with different sensitivities.

Request technical documents for these models

Digital dynamometers BASE model

Features:- Display with reversible lettering

- Excellent price/performance ratio

- Sampling 1000 readings per second

- For tensile and compressive testing

- Ergonomic design in die-cast aluminium

- With max. capacity up to 1kN

- Overload resistance up to 200% f.s.

- Programmable setpoints for go/no go testing

- USB and RS-232C outputs

- Real-time or peak mode reading

- Internal rechargeable NiMh battery

- Battery operating time 30 hours

Request technical documents for these models

Digital dynamometers model EVOLUTO

Additional functions:- INTERNAL MEMORY: Non-volatile memory with 1000 numerical values that can be recalled on the display or transferred to a PC.

- CONTINUOUS PEAK RECORDING: Once the threshold of 10% of the F.S. of the dynamometer has been exceeded, the instrument continuously records the peak data based on the decrease in force when it falls to 7% of the full scale value.

- SLOPE DETECTION: Stores the slope for manual tests at a certain slope with an alarm function if the instrument loses the preset slope.

Inserts for dynamometers

Request technical documents for these models

They are available in various versions for capacities from 2N to 5000N with different sensitivities.

STANDARD series professional digital dynamometers

Features:- Display visible even in the dark

- Multilingual settings menu in Italian

- 2000 Hz sampling rate

- Limits with acoustic warnings and warning lights

- Ergonomic design in die-cast aluminium

- With max. capacity up to 1kN

- Overload resistance up to 200% f.s.

- Internal memory records up to 1000 values

- Transmits data to PC via USB

- USB, RS-232C, Digimatic and Analogue outputs

- Real-time or peak mode reading

- Internal rechargeable NiMh battery

Professional digital dynamometers ADVANCED series

Additional functions:- FORCE/DISTANCE: Displays both force and displacement data when combined with encoder stands.

- USB PENDRIVE: Readings can be transferred from internal memory to a USB Pendrive or saved directly to it (sampling rate 100 data/sec).

- SENDING DATA TO EXTERNAL DEVICES: 2 adjustable high/low output values. If the reading reaches one of the values, the data will be sent to external devices for recording.

- 2 Peaks: Can detect two peak values per measurement.

Inserts for dynamometers

Series of dynamometers with special uses

Professional digital dynamometers HIGH CAPACITY series

High-capacity digital dynamometers for mechanical testing. The hand-held unit is made of reinforced baked painted die-cast aluminium and has two side holes on which the two supplied handles can be screwed to allow a firm grip. The internal sensor is a high-precision load cell of the bidirectional type, for direct tensile and compression tests.Thread M10 for connecting inserts.

Professional digital dynamometers with EXTERNAL SENSOR

The dynamometers consist of a handheld unit and an external sensor, also known as a load cell, connected by cable. They are ideal for all applications requiring a compact instrument that is easy to transport, simple to use and independent of power sources. The external sensor also facilitates measurements in narrow places that are difficult to reach. The unique feature is the high sampling rate of 2kHz, which allows even fast-moving phenomena such as the breaking of fragile materials (glass or ceramics) to be measured with great accuracy. The dynamometers are available in standard and advanced versions.Portate maximum of 2 to 20Kn depending on the model.

Force measurement sensors and load cells

Capacity2N - 20kN

Traction and compression

Ideal for production lines

Capacity100N - 20kN

Traction and compression

Waterproof sensor

Small Capacity50N - 2000N

Traction and compression

Diameter28 mm

Extra Small

Capacity50N - 500N

Traction and compression

Diameter18 mm

Request technical documents for these models

Capacity: 1000N - 20kN

Traction or compression

Waterproof sensor

Capacity10kN - 20kN

Traction

Waterproof sensor

Capacity: 5000N - 20kN

Compression

Waterproof sensor

Request technical documents for these models

Pen-shaped sensor

Capacity: 50N

Compression

Handy as a pen

Cubiform load cell

Capacity: 2000N-20kN

Traction or compression

Waterproof sensor

Button sensor

Capacity10N - 20kN

Compression

Ideal for tight spaces

Request technical documents for these models

Sensor with hook

Capacity: 10kN

Traction

Waterproof sensor

Door test sensor

Capacity0.5/2/5/10 N-m

Special applicationsfor automatic door closing test

Sensor for testing car windows

Capacity: 1000N

Car window closing test

IP65 protection

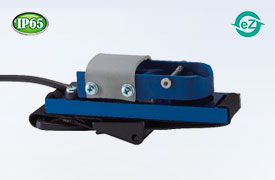

Motorbike brake sensor

Capacity: 500N

Special applications

IP65 protection

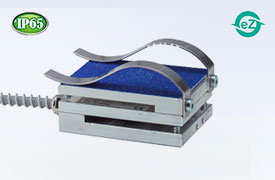

Car brake sensor

Capacity: 1500N

Special applications

IP65 protection

Request technical documents for these models